Liquid Metal Epoxy Coating

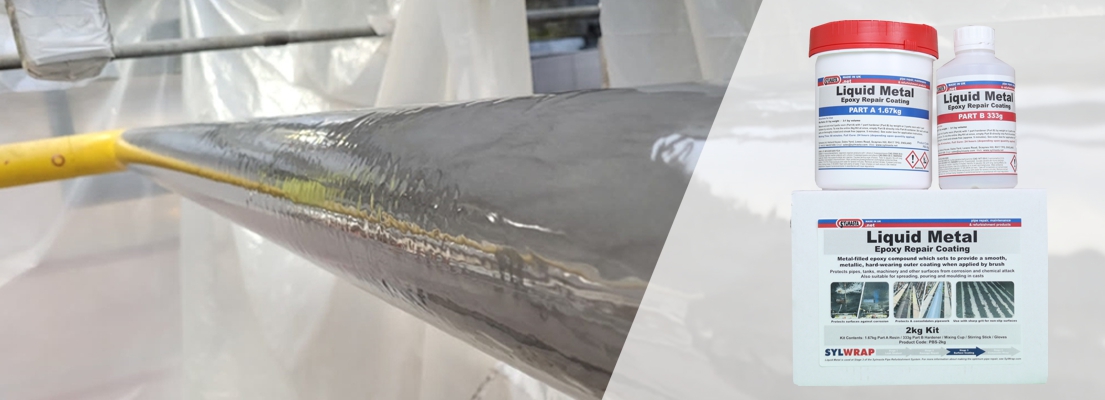

Liquid Metal is a metal-filled protective epoxy coating applied to pipework to protect against corrosion and increase chemical resistance.

It is brush applied and sets to a smooth, metallic, hard-wearing layer which protects pipes made of steel, other metals and most plastics from external corrosion and chemical attack.

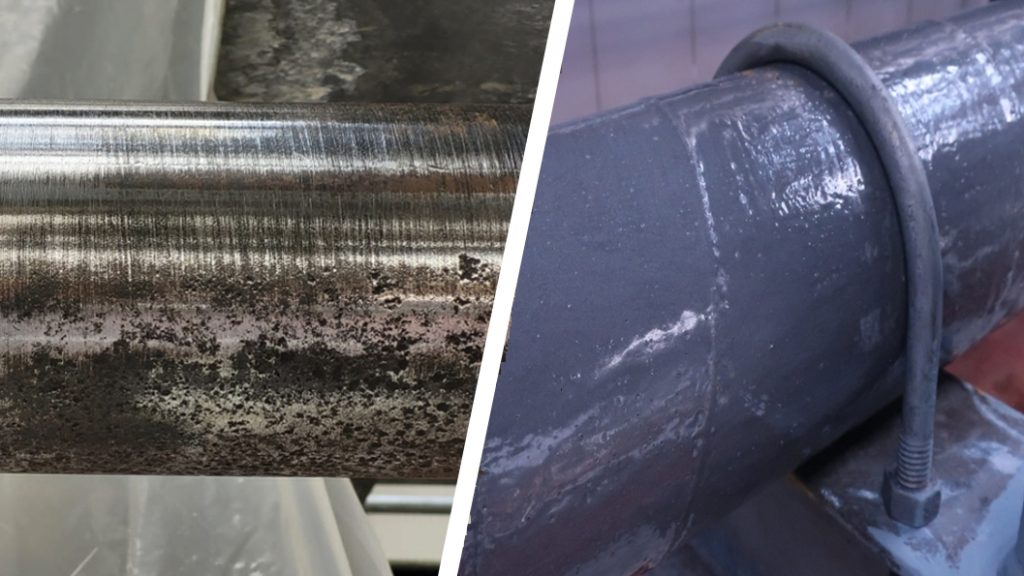

Liquid Metal also protects pipework from internal corrosion by creating an impermeable membrane around a pipe, capable of withstanding future breaches from inside and containing pipe content.

Coating a pipe in Liquid Metal improves surface adhesion between pipework and a composite repair wrap like SylWrap Pipe Repair Bandage added at Stage 4 of the Sylmasta Pipe Refurbishment System.

This subsequently increases the effectiveness of the protective layer provided by the composite wrap. When applied with SylWrap Bandage, Liquid Metal can also be used as a load-transfer layer providing, PCC-2 compliant repairs.

The light consistency of Liquid Metal makes it easy to mix and apply with little sag. This ease of application makes it suitable for repairing elbow joints, flanges, tanks, valves, water box ends, impellers, pump, and metal castings in industrial settings.

It is virtually odourless, with no unpleasant smell, can be easily machined and is temperature resistant to 150°C. To protect pipework exposed to temperatures in excess of 150°C, please see Titanium Supergrade HT Epoxy Paste.

Liquid Metal has a gel times of 90 minutes, allowing more Coating to be mixed and applied over large areas without the treat of premature curing. Sylmasta recommend the use of Liquid Metal for applications in hot climates and at higher ambient temperatures because of its longer work time.

How to protect pipework using Liquid Metal Epoxy Coating

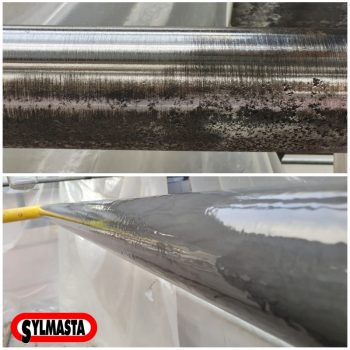

Before Liquid Metal Protective Epoxy Coating can be applied, the pipework requiring protection or repair must be prepared.

All paint, rust and grime must be removed either via abrasive blasting or with sandpaper and surfaces should be dry and free of grease.

The pipe must be roughened first to improve the grip of the Liquid Metal coating to the substrate. Liquid Metal should be applied as soon as possible after preparation of the pipework.

Part A and Part B are mixed together in the ratio prescribed and then brushed over the area requiring protection.

Each coating should be 0.5-1.00 mm and at least two coats are needed to ensure a pinhole-free coating. The re-coating time between coats is approximately 5-8 hours after applying. A full functional cure is achieved 24 hours after the final coat.

When applying a composite wrap over Liquid Metal, the wrap should be applied once the layer of Epoxy Coating has gelled but remains tacky.

To determine the quantity of Liquid Metal needed for a specific application, please go to the Repair Calculator Tab and enter your repair data.

Applications

- Protection of metal and plastic pipes in industry from external corrosion and chemical attack

- Forming an impermeable membrane around pipework to prevent breaches caused by internal corrosion

- Increasing adhesion between composite wraps and pipework

- Load transfer layer when used with SylWrap Pipe Repair Bandage

Benefits

- Easy to mix and apply – simply brush onto pipework

- Long working time enables larger, complex sections of pipes to be coated

- Can be easily machined

- Makes PCC-2 compliant repairs when used with SylWrap HD

Technical Data

Mix Ratio:

5:1 weight.

3:1 volume.

Gel Time:

90 minutes.

Re-coat Time:

4-8 hours.

Full Cure:

24-48 hours.

Thickness Per Coat:

0.5mm-1.0mm.

Shore D Hardness:

>80 (24 hour full cure).

Tensile Strength:

28 MPa.

Compressive Strength:

59 MPa.

Flexural Strength:

58 MPa.

Density:

1.55 (gm/cm³).

Heat Distortion:

50°C cured at room temperature.

117°C post cured.

Maximum Service Temperature:

150°C.

Full TDS Downloads

Liquid Metal Epoxy Coating Case Studies

Industrial Plant Refurbish 3 Metre Section of Corroded Steel Gas Pipe in CHP System

Landfill Site Encapsulate Decommissioned Drainage System Capped Pipe Stub

South Wales Corroded 20-Metre Long Steel Pipe Bridge Repair & Refurbishment

Valve Chamber Below Specification 22 Degree Elbow Bends Reinforcement

Liquid Metal Epoxy Coating Repair Calendar

The Liquid Metal Calculator determines the quantity of Epoxy Coating needed to repair a specific damaged section of pipework.

Enter the diameter of the pipe in millimetres, the length of the repair area and the coating thickness of Liquid Metal to be applied.

Once you have entered your data, press calculate and the number of kilograms of Epoxy Coating required will be shown.

Full TDS Downloads

Please use the below form to enquire about the price and availability of Liquid Metal Epoxy Coating

Related Corrosion Protection Products

Titanium Supergrade HT Epoxy Paste

Titanium Supergrade HT is an alloy-reinforced epoxy paste with high compressive strength for protecting metal and plastic pipes exposed to temperatures up to 250°C. It is applied with a hand tool and has a three-hour work time for use in the most complex of applications.

Number of Repairs: Multiple

Work Time: 180 Minutes

Temperature Resistance: Up to 250°C

Sylmasta E190 Brushable Epoxy Resin

E190 is an epoxy resin coated onto surfaces and layered with Fibreglass Tape, building a composite repair. It is used when a repair wrap cannot be effectively applied, such as to complex pipes or tanks, and can be specially formulated for specific applications.

Number of Repairs: Multiple

Work Time: 30 minutes

Specialist resins can be formulated for temperature, chemical resistance, etc

SylWrap CR Corrosion Protection Wrap

SylWrap CR is a pipe repair bandage infused with corrosion inhibitors to further protect pipes in harsh, aggressive environments including marine and underwater against substrate corrosion.

Number of Repairs: One Per Bandage

Requires Diisocyanate Training: No

Work Time: 2–5 minutes

Temperature Resistance: Up to 120°C