Power Plant Pipe Repair

When critical pipework in a power plant fails, SylWrap products provide permanent pipe repair and refurbishment solutions without the need for a costly and disruptive shutdown of systems.

Pipes are integral to the operating efficiency of power plants, no matter what power source the facility is using. If pipework fails, plants may have to shutdown generators whilst damaged sections are repaired or replaced.

This reduces the capacity of the plant to generate power, which has a direct impact on the efficiency of the network the plant is supplying.

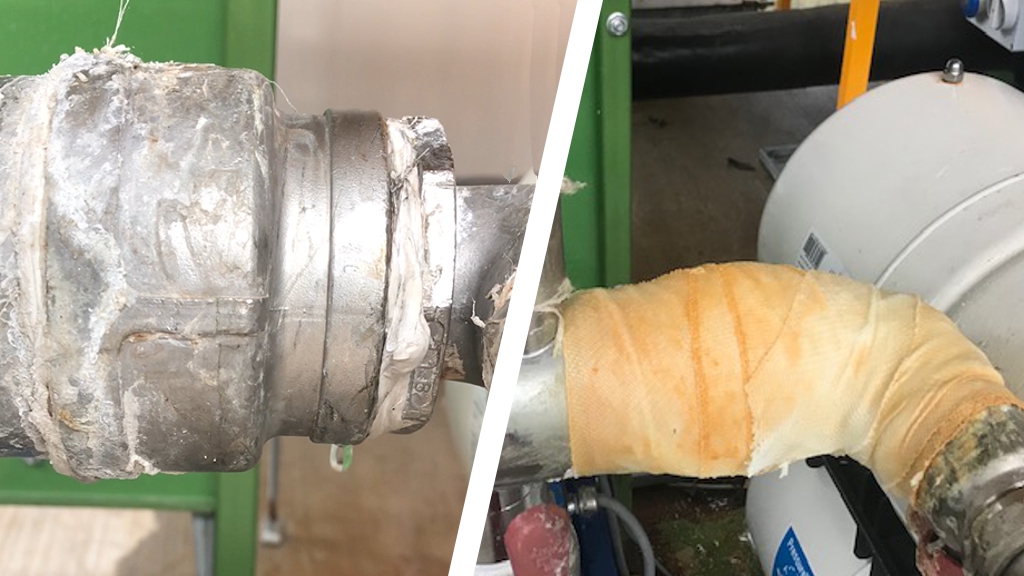

A SylWrap Leak Repair does not require systems to be taken out of service. Leaking pipes can be fixed whilst the power plant remains operational. Repairs take under 30 minutes, require no formal training and are effective on pipes of all substrates and sizes.

The toughest Sylmasta products can withstand pressure up to 30 bar and temperatures up to 300ºC, making them suitable for the most extreme environments. Sylmasta products have been used in power stations, nuclear plants, and CHP Systems to carry out permanent, live leak repairs.

Keeping a SylWrap Contractor Case on site enables power plants to seal leaks as soon as problems arise. Each Case contains enough products to make up to six live leak repairs on pipes of varying diameters. In emergencies, plant engineers simply reach for their Case for an instant repair.

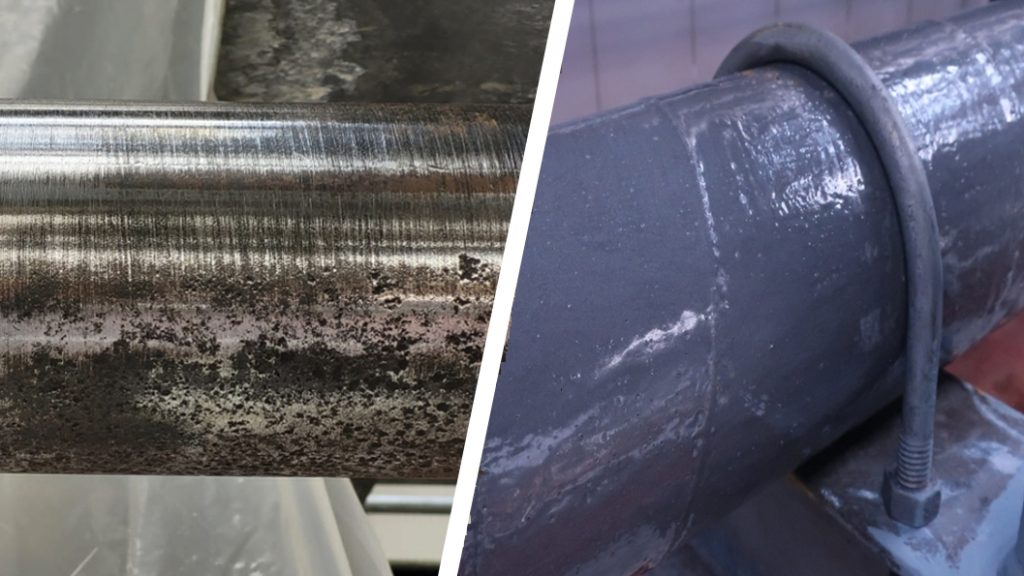

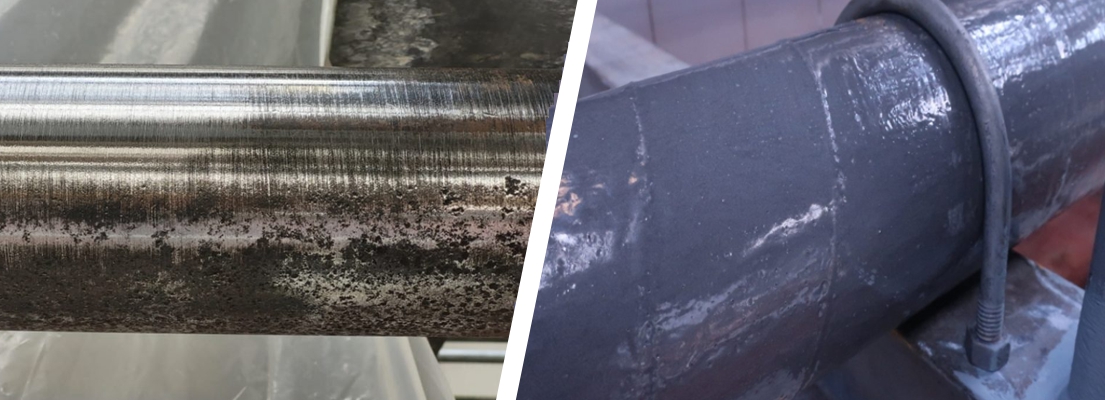

Leaks and bursts can be avoided all together if pipes are protected and maintained. The four-stage Sylmasta Pipe Refurbishment System reinforces and protects pipework at power plants before failure can occur.

It strengthens and rebuilds weakened pipelines, protects against corrosion, chemical attack and other external factors, and reduces the risk of future leaks and breaches from occurring.

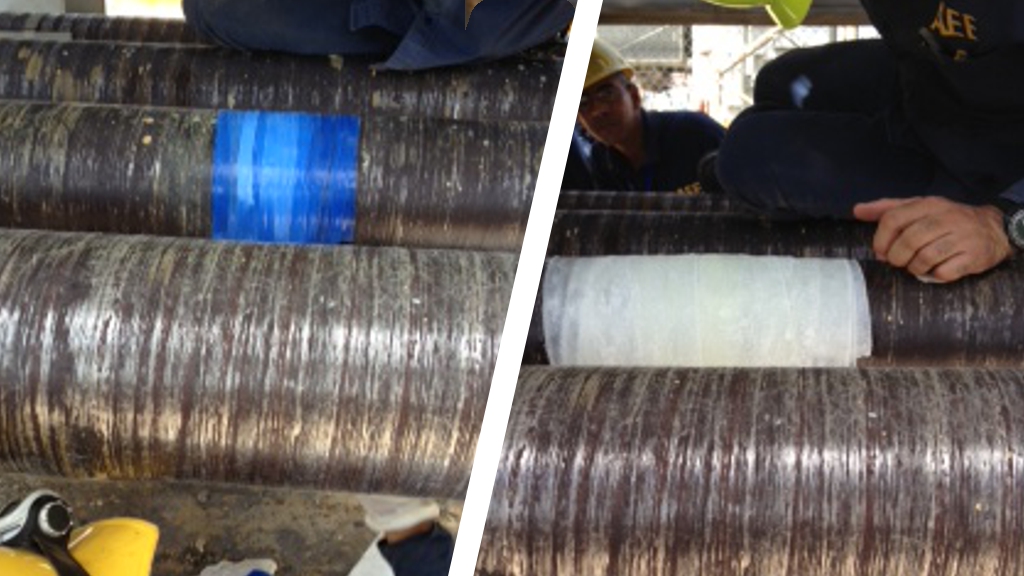

Pipe Repair and Protection Applications made in Power Plants with SylWrap

Industrial Plant Refurbish 3 Metre Section of Corroded Steel Gas Pipe in CHP System

Pig Farm Biodigester Tank Leaking Stainless Steel Heating Pipe Repair

Puerto Rico Power Station Cooling System Leaking Hydrogen Line Pipe Repair

Biomass Power Plant Heating Tank Stainless Steel Pipe Repair

CHP Plant High Temperature Pipe Leaking Elbow Joint Repair

Puerto Rico Power Plant Cracked Contaminated Water Pipe Live Leak Repair

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com