Industrial, Factory and Workshop Pipe Repair

Pipes are found everywhere in industrial, factory and warehouse environments and when leaks occur or pipelines require strengthening, SylWrap Pipe Repair Kits and the Sylmasta Pipe Refurbishment System keep downtime and disruption to a minimum.

The repair of damaged pipework in a factory or workshop can be a complicated procedure. Pipes are often not accessible, positioned against walls or as part of roof structures which rules out bulky, heavy clamps as a repair method.

Depending on the industry, the pipework in question might be subjected to extreme temperatures or aggressive chemicals. Repairs need to be able to withstand such conditions.

One of the most damaging aspects of leaking pipes in factories and workshops comes from disruption. Shutting down systems until a specialist engineer is for repair or replacement is costly in terms of lost production time, purchasing of new parts and labour required to fit them.

SylWrap Pipe Repair Kits provide an alternative, enabling any user to fix a leaking pipe in 30 minutes. Repairs are pressure resistant to 30 bar, temperature resistant to 120ºC, and flexible enough to be made to pipe elbows, tees and other challenging and restricted sections.

Factory and workshops across a wide range of sectors have used both the Standard Pipe Repair Kit and the Universal Pipe Repair Kit to fix leaks within their premises at a fraction of what a full system replacement or repair carried out by a professional contractor would have cost.

For businesses with large warehouse facilities or maintenance and facilities management companies responsible for numerous sites, there is the SylWrap Pipe Repair Contractor Case.

Each Case contains enough products to seal up to six live leaks at a cheaper cost-per-repair than purchasing individual kits. The Contractor Case can be easily stored on site, leaving it close to hand for whenever an emergency pipe repair needs to be carried out.

In factories and industrial sites where older pipework is present, the Sylmasta Pipe Refurbishment System extends the lifespan of pipes before leaks can occur and as an alternative to replacement.

The four-stage process rebuilds and strengthens weakened and degraded sections and protects against corrosion, chemical attack, wear, abrasion and impact damage, lessening the chances of future leaks and breaches.

SylWrap Pipe Repairs in Industrial, Factory and Workshop Settings

Costa Rica Sugar Mill Live Leak Pipe Repair of 70mm Alcohol Line Operating at 2 Bar

Industrial Plant Refurbish 3 Metre Section of Corroded Steel Gas Pipe in CHP System

Argentina Chroming Factory Reinforce Welded Corners in Chromic Acid Tank

Landfill Site Encapsulate Decommissioned Drainage System Capped Pipe Stub

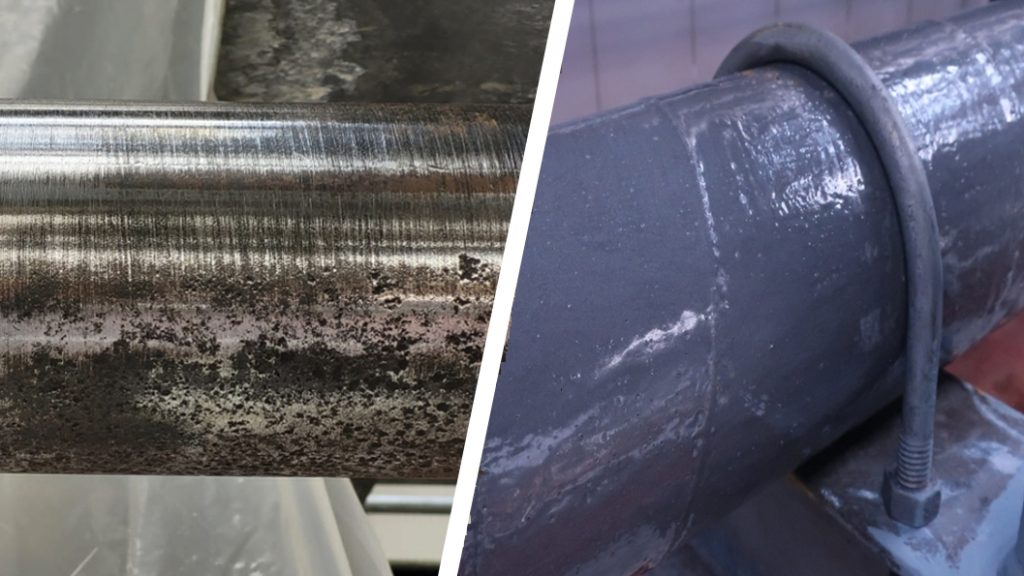

Industrial Site Rebuild & Reinforce Heavily Corroded 2 Metre Section of Steel Pipe

Fire Station Water Pumping House Corroded Steel Pipe Reinforcement

Quarry Wash Plant 150mm Steel Pipe 90 Degree Elbow Bend Leak Repair

Saudi Arabia Desalination Plant 3000mm Partially Buried FRP Discharge Pipe Repair

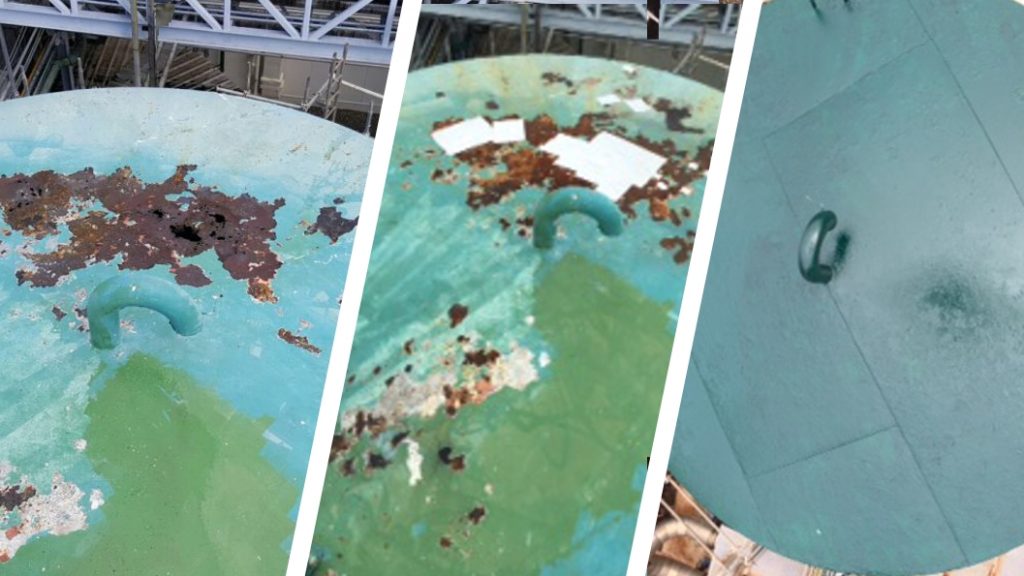

Puerto Rico Pharmaceutical Plant Corroded Tank Repair & Refurbishment

Seawater Cooling System 1500mm Pipe Supply Line Leak Repair & Reinforcement

Saudi Arabia Cracked 250mm PCCP Stub Live Leak Pipe Repair & Reinforcement

Quarry Aggregate Wash Plant Pierced 300mm Plastic Pipe Pinhole Repair

Furniture Factory Steel Sprinkler System Pipe Pinhole Leak Repair

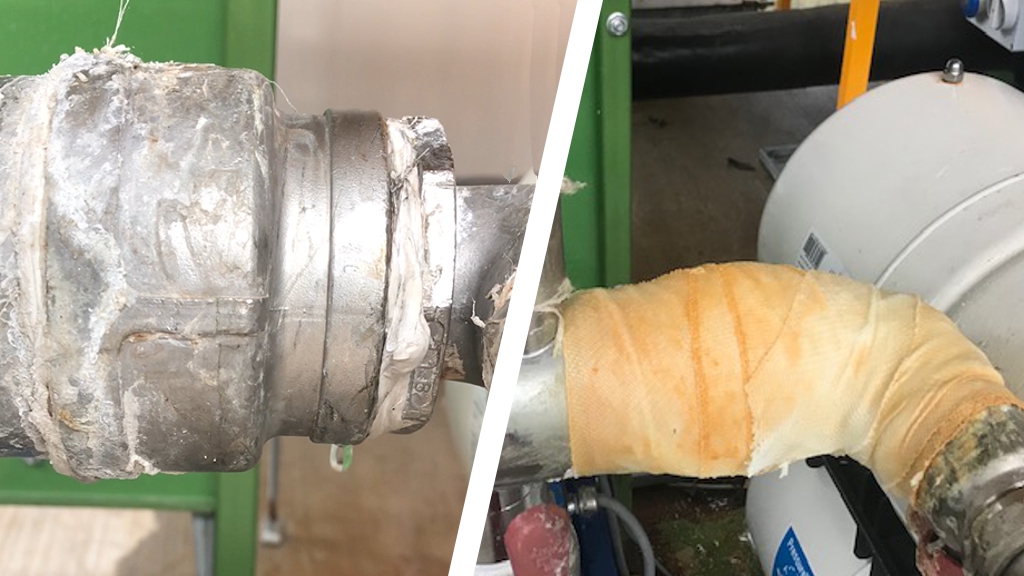

CHP Plant High Temperature Pipe Leaking Elbow Joint Repair

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com