SylWrap Pipe Repair Kits and the Sylmasta Pipe Refurbishment System have provided industry-leading solutions for the repair, maintenance and refurbishment of pipelines worldwide, as highlighted by the following Case Studies.

Sylmasta’s clients include water utility companies, infrastructure operators, facilities management teams, oil refineries, petrochemical plants, mines and government departments.

Projects range from major steel pipelines operating at vast oil refineries in Iraq to the public water supply network in Mexico to leaking copper pipes in a domestic kitchen.

Most of the products in the Leak Repair Range have WRAS Approval, meaning they are certified to British Standards as safe to use with drinking water.

Repairs made using SylWrap comply with Regulation 31 of the Water Supply Regulations and meet the standard of ASME PCC-2-2015 for the Repair of Pressure Equipment and Piping.

No application is too big (or too small) and Sylmasta technicians are always available to help offer assistance in finding a repair method in complex and challenging scenarios.

If you have a pipe repair application which requires technical advice or have seen a Case Study you would like to know more about, please contact Sylmasta via email or by phoning +44 (0)1444 831459.

A 1.05-metre long crack in an internal cast iron downpipe leaking rainwater into a hospital ward is sealed within 30 minutes of being discovered with no disruption to patients or staff

An office block refurbishment is kept on track as 300 corroded joints in an internal rainwater stack are sealed to avoid replacing 250 metres of cast iron pipe running through five floors

A water company take corrosion protection measures for a complex 600mm ductile pipe system showing signs of surface damage in an underground pumping station

Having a SylWrap Pipe Repair Contractor Case on site enables a sugar mill to make an instant live leak repair to an alcohol line, avoiding downtime during the short sugar milling season

Four cottages in a terrace of eight repair their respective sections of a 48 metre shared water supply pipe breached by corrosion after low-quality lagging trapped moisture against the line

Wastewater holding tanks underneath luxury portable toilet trailers are repaired to avoid decommissioning and replacing two expensive units otherwise in good working condition

A homeowner repairs a hairline crack around the diameter of a porcelain soil pipe caused by an unstable bathroom floor pulling a toilet away from the wall it was connected to

An industrial plant refurbish a 3 metre section of steel pipe carrying natural gas as part of the site’s CHP system which had been weakened by heavy corrosion

Leaks at both ends of a saddle joint welded onto a 150mm steel pipe are sealed at a pumping house in Malaysia despite a 20mm step between the line and the joint

A gas plant in Saudi Arabia fill in cracks discovered in the rubber floor of a seawater storage tank which had left the concrete coating underneath dangerously exposed

A cement coated steel pipe on a water network in Mexico undergoes a live leak repair after removal of the outer coating revealed a 80mm long split in the line

When UK temperatures dropped to -15°C, owners of horse showers supplied by Showerking were directed to repair burst pipes within their units using SylWrap

A natural gas pipeline is protected against potential scarring and impact damage ahead of being rerouted beneath a river and road via horizontal directional drilling

A pig farm seals a leaking heating pipe inside a biodigester tank damaged by a metal pillar connected to a mixer blade after an initial patch welding repair attempt failed

New corners welded in place during the repair of a corroded chromic acid tank are reinforced using patches of SylWrap Pipe Repair Bandage for additional sealing security

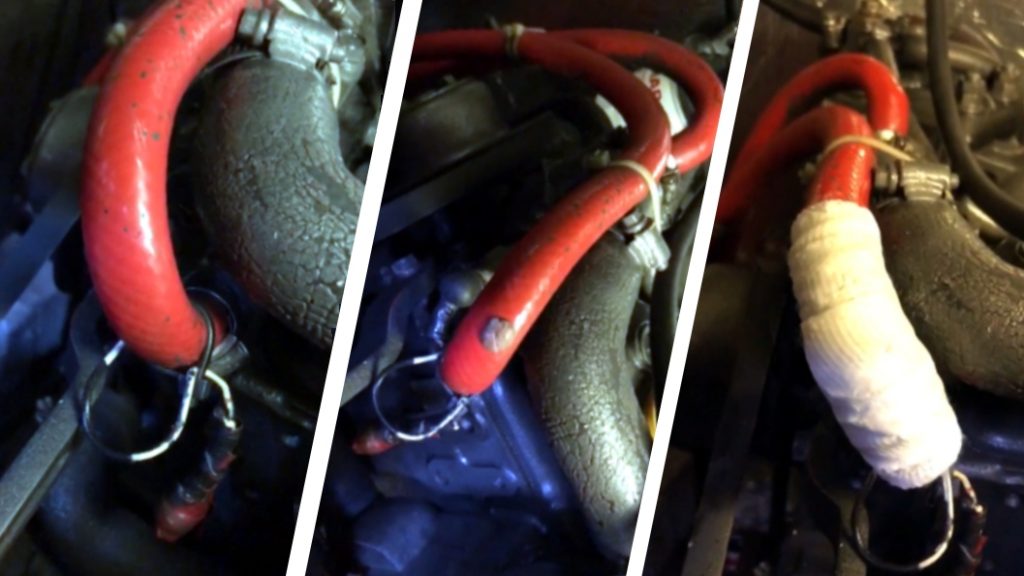

A rubber hose operating as part of a boat engine cooling system is repaired after developing a pinhole leak in a below deck area of the vessel which was difficult to access

The UK Environment Agency repair a 700mm long crack in an underwater wall through which water was escaping from a river and into a privately owned trout farm

A 18000mm underground pipe at a wastewater treatment plant is sealed and protected against tree root ingress after the line was penetrated between flange plates

The decommissioning of an underground drainage system at a landfill site required a capped pipe stub to be encapsulated for protection against corrosion

A chemical plant accesses, excavates and repairs a leaking effluent pipe running under salt marshes and out to sea in an eight hour window whilst the tide was out

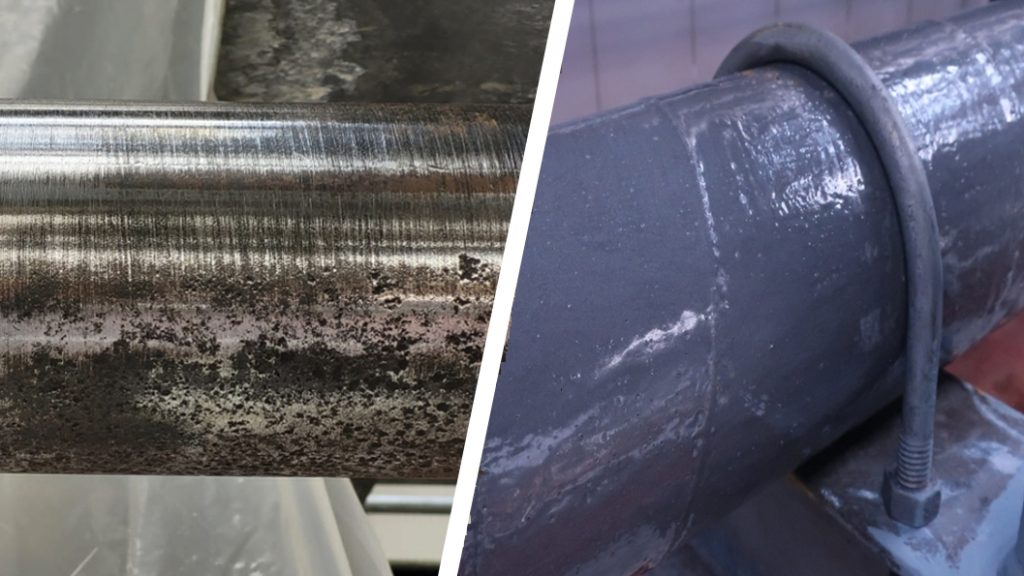

An industrial site rebuild and reinforce a 2 metre section of heavily corroded steel pipe before the line became breached and required a complex repair or replacement

An oil refinery avoid weeks of downtime awaiting installation of a new GRP seawater cooling system pipe by sealing several leaks in a repair completed in two days

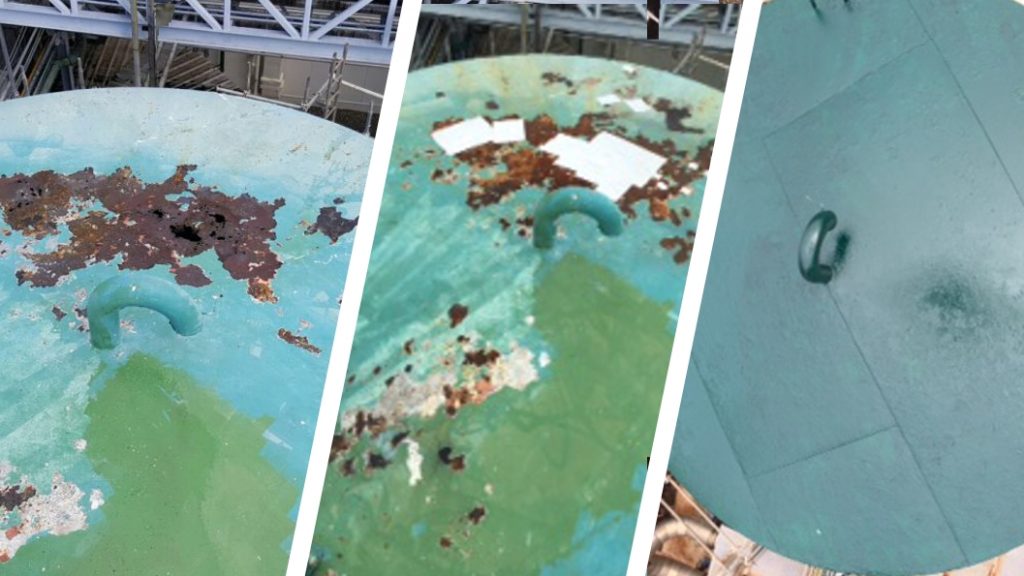

A dilapidated, corrosion-covered 20-metre long steel pipe bridge crossing the Rhonda River is repaired and refurbished to save a water company the expense of replacement

Above and underground water supply pipes servicing a town in Libya required live leak repair to seal cracks with minimal disruption to homes and businesses

A hydrogen line newly installed in a power station cooling system undergoes repair and reinforcement after it was found to be leaking from two joints 600mm apart

An oil refinery repair surface damage which had weakened a 400mm GRP pipe, strengthening and restoring the integrity of the line to lessen the chance of future leaks

A 50mm crack left between a toilet waste pipe and a bathroom floor during renovation work required filling to complete connection of the toilet to the sewer

A homeowner makes a quick, easy and inexpensive DIY repair to a cracked PVC plastic pipe leaking from several holes in a cupboard below a bathroom sink

A 6 metre section of 150mm steel pipe containing two elbow bends at a fire station in Saudi Arabia is reinforced before heavy corrosion could breach the line

A quarry who previously repaired all leaks on site using clamps required a more versatile method when a pinhole leak developed close to a 90 degree elbow bend

Problems during installation of a 3000mm FRP line at a desalination plant left gaps in the partially buried pipe which had to be sealed before the facility could go online

An energy company reap the benefits of carrying SylWrap Contractor Cases on their vans by making a rapid live leak repair to a steel district heating pipe in a ceiling cavity

The repair of a 90-year-old malleable iron pipe for which replacement fittings were no longer made avoided digging out and replacing an entire water supply line

A pharmaceutical plant keep a large tank operational by patch repairing numerous cracks and refurbishing extremely brittle metalwork suffering from heavy corrosion

A live leak repair to a wastewater pipe breached during construction work at a treatment plant prevents a potentially damaging environmental incident occurring

An engineering team in Malaysia repair a 900mm steel water main leaking from a cracked flange in a flooded underground chamber previously thought to be unfixable

A 20mm malleable iron water pipe at a domestic property undergoes repair despite space being severely restricted by the proximity of the leaking section to a wall

A seawater cooling line in Saudi Arabia undergoes repair and reinforcement after a snapped nozzle created a 50mm hole and a 5 metre vertical discharge of water

A water company in Malaysia repair a 150mm steel elbow at a pumping station after corrosion caused a pinhole, through which water was jetting at 6 bar pressure

An underground 200mm fuel line in Libya undergoes a leak repair pressure resistant to 44 bar after corrosion caused a crack to appear through which oil was escaping

Bahrain Airport avoid having to shut down an important system to fit replacement parts by making a live repair to a 100mm UPVC pipe leaking from a step joint

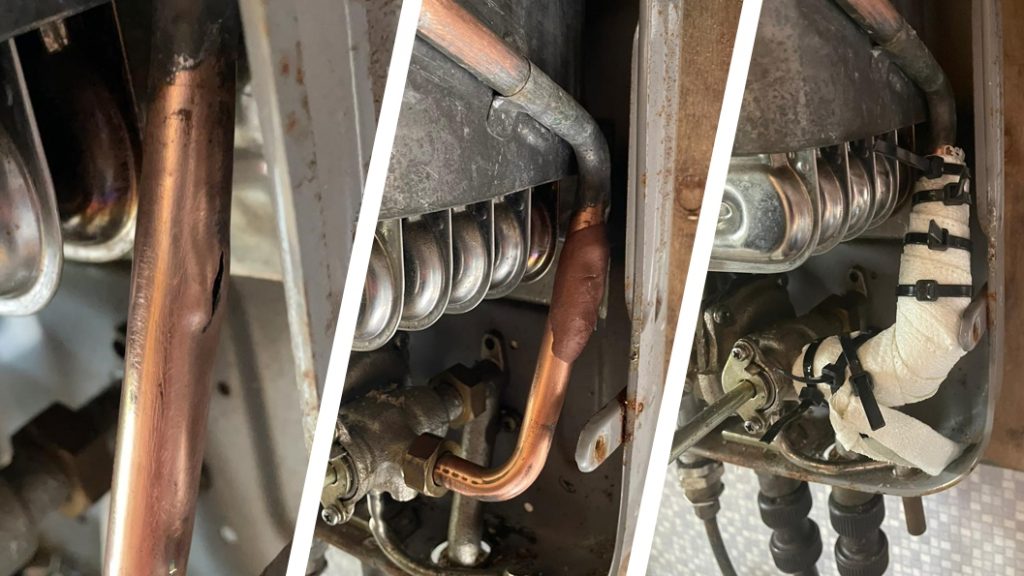

A cracked copper pipe in a camper van boiler system spraying a pressurised jet of water whenever the boiler was turned on is sealed in a DIY pipe repair by the van owner

A petrochemical refinery in Saudi Arabia reinforces an elbow on a 22 bar sulphuric acid line after it was discovered to have degraded to just 1mm thickness

A water company repair two faulty couplings connecting a section of 650mm pipe to a mains water line discovered to be leaking within a disused inspection pit

An engineering company in Saudi Arabia make a live leak pipe repair to a cracked PCCP stub with no isolation valve operating under 4 bar pressure

A London Hospital make an emergency repair to a burst pipe which had forced the shutdown of the air conditioning system on a day when temperatures hit 27ºC

A water utility company in Mexico repair a buried 600mm asbestos cement pipe after discovering it was leaking from both ends of a sleeve

A quarry repairs a 300mm plastic pipe in its aggregate wash plant which was suffering from a pinhole leak after becoming pierced during day-to-day operations