Pharmaceutical Plant Corroded Tank Repair & Refurbishment

A pharmaceutical company patch repair a heavily corroded industrial tank at their plant in Puerto Rico, sealing numerous cracks in the roof and protecting the metalwork from further corrosion to keep the tank operational until a scheduled replacement in several years time.

Case Study Overview

Site Pharmaceutical plant

Location Puerto Rico

Repair Type Tank repair & corrosion protection

Products E190 Brushable Epoxy, Fibreglass Tape

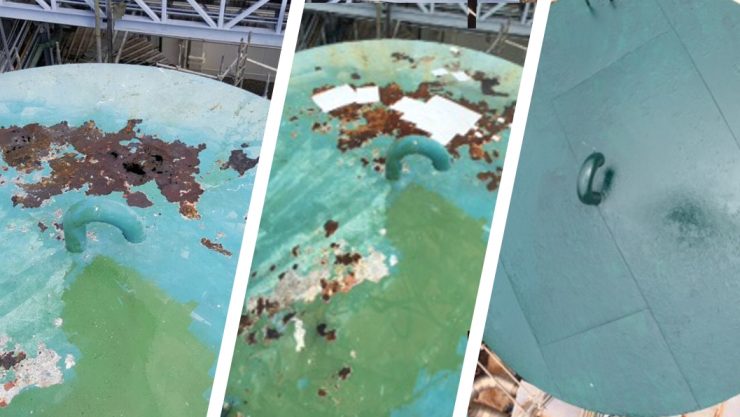

Tank Defect

The tank was suffering from heavy corrosion, especially at the top. The pharmaceutical company operating the plant had been hoping to keep the system operational until the scheduled replacement of the tank in several years time.

Unfortunately, the corrosion became so bad that a repair had to be made. The primary consideration for the repair was cost; the company did want to go spending thousands of dollars repairing and refurbishing the tank, only for it to be condemned in the near-future.

Sylmasta originally recommended coating the tank with Ceramic Brushable Green Epoxy Coating, creating a silicone carbide reinforced protective layer with high corrosion and abrasion resistance.

Before Ceramic Brushable Green could be applied, paint, rust and grime had to be removed. During this process, several cracks appeared in the roof of the tank owing to how brittle the metalwork had become.

These cracks now required sealing via a patch repair before the corroded tank could be painted with Ceramic Brushable Green, making the application more complex than it had initially appeared.

Solution

The cracks in the roof of the tank were bridged using E190 Brushable Epoxy Resin and Fibreglass Tape, creating a composite patch repair. Strips of Fibreglass Tape were cut off, soaked in E190 and then stretched over each crack.

E190 has a work time of 30 minutes, after which the resin-soaked Fibreglass cured to form a rock-hard material sealing all holes. The application continued with several layers of E190 and Tape being built up until the team carrying out the repair were satisfied that each crack had been suitably arrested.

Once the composite patch repair stage had been completed, the tank was covered in three coatings of Ceramic Brushable Green. A brushable epoxy coating similar to Liquid Metal Epoxy Coating, Ceramic Brushable is filled with silicone carbide rather than metal.

It cures to create an ultra-smooth, hard-wearing material which seals surfaces and protects against chemical attack, cavitation, erosion and pitting, as well as corrosion.

Outcome

The entire repair of the corroded tank was completed in a little over 48 hours. E190 Brushable has a full cure time of 24 hours from the final coating, as does Ceramic Brushable.

Once finished, the application ensured that there were no remaining breaches in the roof of the tank. The whole structure was suitably reinforced against future corrosion and protected from environmental elements.

Follow up

Complications down the line meant that the planned replacement of the tank eventually had to be suspended. Five years later and the refurbished tank was still in service, fully functional and with no further signs of corrosion.

Products Used

E190 Brushable Epoxy Resin

Used with Fibreglass Tape to build composite patch repairs where wraps cannot be applied

Related Case Studies

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com