E190 Epoxy Composite Repair Kit

The Epoxy Composite Repair Kit contains high-strength Sylmasta E190 Brushable Epoxy Resin and Fibreglass Tape. It makes more versatile patch repairs to complex sections of pipework and tanks where direct wrapping is not possible.

E190 Brushable Epoxy Resin is either brushed directly onto surfaces and overlaid with Fibreglass Tape, or coated onto strips of Fibreglass Tape which are then applied to areas requiring repair.

The resin-coated Tape will cure to form a rock-hard, impact-resistant outer shell. It protects, reinforces and refurbishes pipes and tanks made of metal, most plastics, GRP and other composites as an alternative to replacement.

Making a patch repair using the E190 Epoxy Composite Repair Kit does require more skill than with straightforward pipe repair bandages such as SylWrap HD.

The advantage is repairs can be made to inaccessible pipes, difficult shapes and tanks which cannot be effectively wrapped using a bandage. The Kit also enables multiple areas of damage to be repaired, whereas SylWrap HD can only cover one section.

E190 Brushable Epoxy Resin has a 30 minute work time, allowing careful application to surfaces or Fibreglass Tape. It is temperature resistant to 100°C and offers excellent protection against corrosion and chemical attack.

Sylmasta can formulate and supply specialist versions of E190 Brushable Epoxy Resin, for example when greater chemical or temperature resistance is required. For more information on custom-made formulations, please contact Sylmasta.

How to make a pipe or tank repair with the E190 Epoxy Composite Repair Kit

Before E190 Brushable Epoxy Resin can be applied to a pipe or tank surface, the substrate requiring protection undergoes preparation. All paint, rust and grime is removed either via abrasive blasting or with sandpaper and surfaces should be dry and free of grease.

The surface must be roughened first to improve the grip of E190 to the substrate. E190 should be applied as soon as possible after preparation of the pipework.

Part A and Part B are mixed together in the instructed ratio. Once mixed, E190 is brushed onto the pipe or tank, followed by a layer of Fibreglass Tape being wrapped over the resin.

The Fibreglass Tape is coated with further E190, before another overlay of Tape is added. The application continues in this way until enough layers have been built to satisfy the repair, with one final coating of E190 added as the final layer.

When it is not possible to wrap Fibreglass Tape because of space constraints or difficult pipework and tank shapes, strips of Tape are instead cut from the roll and pressed onto a surface coated wih E190.

Alternatively, the Fibreglass Tape can be coated in E190 and then applied to the substrate. Full instructions and guidance for different repair methods are available on the Technical Data Sheet.

E190 Brushable Epoxy Resin has a work time of 30 minutes and a hard dry of 16 hours. A full cure is achieved in 24 hours, dependent on thickness of application and cure temperature.

Applications

- Steel pipe composite repair, iron pipe composite repair, copper pipe composite repair, PVC plastic pipe composite repair, GRP pipe composite repair

- Composite patch repair and refurbishment of complex and inaccessible pipes and tanks

- Protection of pipework from corrosion and chemical attack

Benefits

- Versatile repair method for pipes which cannot be accessed or wrapped effectively using a composite repair bandage

- 30 minute work time of E190 enables more careful application in difficult repairs

- Multiple areas can be repaired and refurbished using one Kit

- Highly customisable solution – specialist E190 Brushable Epoxy Resin can be formulated for specific repairs, such as high temperature or extreme chemical resistance

Technical Data

Mix Ratio:

2:1 by weight and volume.

Gel Time:

30 minutes.

Thin Film Set:

6 hours.

Full Cure:

24 hours.

Shore D Hardness:

81 (24 hour full cure).

Tensile Strength:

50 MPa.

Compressive Strength:

59 MPa.

Flexural Strength:

85 MPa.

Density:

1..12 (gm/cm³).

Shrinkage:

<1%.

Non-Volatile Content:

100%.

Maximum Service Temperature:

100°C (dry).

Full TDS Downloads

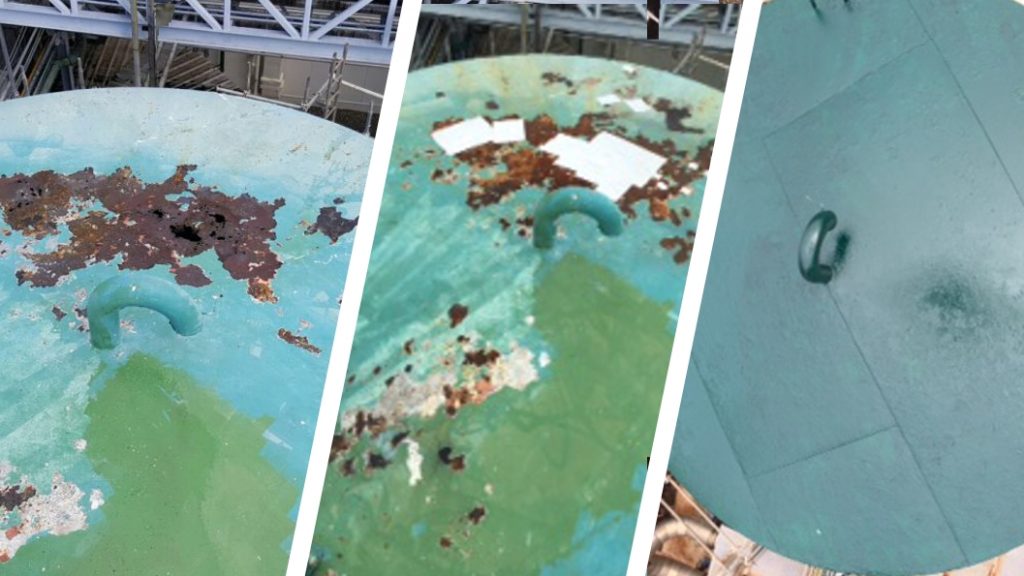

E190 Epoxy Composite Repair Kit Case Studies

Saudi Arabia Desalination Plant 3000mm Partially Buried FRP Discharge Pipe Repair

Puerto Rico Pharmaceutical Plant Corroded Tank Repair & Refurbishment

Please use the below form to enquire about the price and availability of E190 Epoxy Composite Repair Kit

Related Composite Repair Products

SylWrap HD Pipe Repair Bandage

SylWrap HD is a low diisocyanate, WRAS approved pipe repair bandage for reinforcing and strengthening pipes of all materials. It increases pressure resistance, chemical resistance and hoop strength.

Number of Repairs: One Per Bandage

Requires Diisocyanate Training: No

Work Time: 2–5 minutes

Temperature Resistance: Up to 120°C

SylWrap CR Corrosion Protection Wrap

SylWrap CR is a pipe repair bandage infused with corrosion inhibitors to further protect pipes in harsh, aggressive environments including marine and underwater against substrate corrosion.

Number of Repairs: One Per Bandage

Requires Diisocyanate Training: No

Work Time: 2–5 minutes

Temperature Resistance: Up to 120°C

SylShield Pipe Weld & Protection Wrap

SylShield is three times the thickness of SylWrap. It is used to protect welds and pipelines which are subjected to intense installation processes or operate in highly abrasive environments.

Number of Repairs: One Per Bandage

Requires Diisocyanate Training: No

Work Time: 2–5 minutes

Temperature Resistance: Up to 120°C