SylWrap Pipe Repair Kits and the Sylmasta Pipe Refurbishment System have provided industry-leading solutions for the repair, maintenance and refurbishment of pipelines worldwide, as highlighted by the following Case Studies.

Sylmasta’s clients include water utility companies, infrastructure operators, facilities management teams, oil refineries, petrochemical plants, mines and government departments.

Projects range from major steel pipelines operating at vast oil refineries in Iraq to the public water supply network in Mexico to leaking copper pipes in a domestic kitchen.

Most of the products in the Leak Repair Range have WRAS Approval, meaning they are certified to British Standards as safe to use with drinking water.

Repairs made using SylWrap comply with Regulation 31 of the Water Supply Regulations and meet the standard of ASME PCC-2-2015 for the Repair of Pressure Equipment and Piping.

No application is too big (or too small) and Sylmasta technicians are always available to help offer assistance in finding a repair method in complex and challenging scenarios.

If you have a pipe repair application which requires technical advice or have seen a Case Study you would like to know more about, please contact Sylmasta via email or by phoning +44 (0)1444 831459.

A property owner repairs a 300mm area of damage including a 80mm split in a buried plastic hose supplying water to a pond after it was cut into with a pruning saw

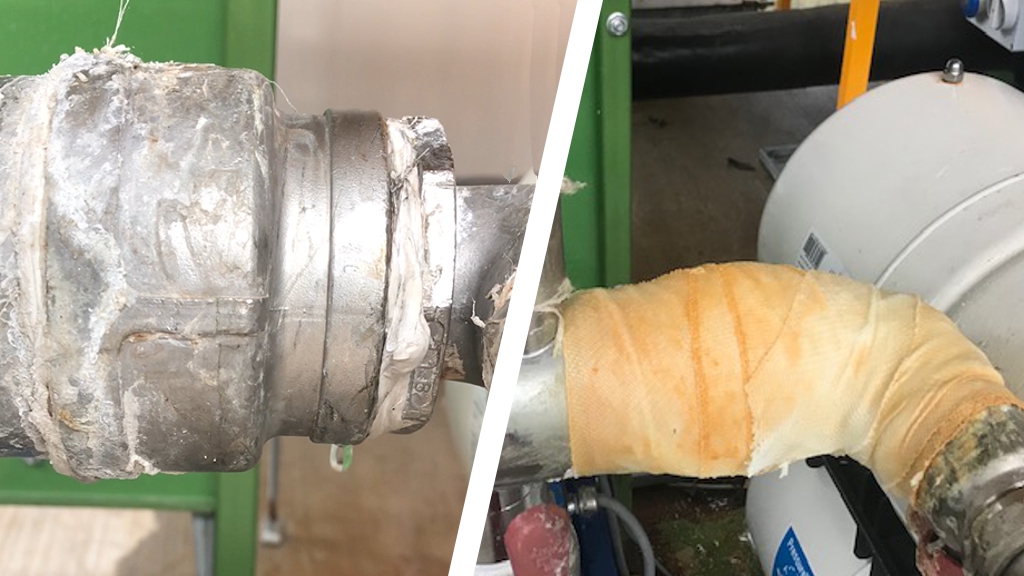

After a 22 degree elbow blew out in a valve chamber due to being below spec, a water company reinforced all remaining joints to prevent similar incidents occurring

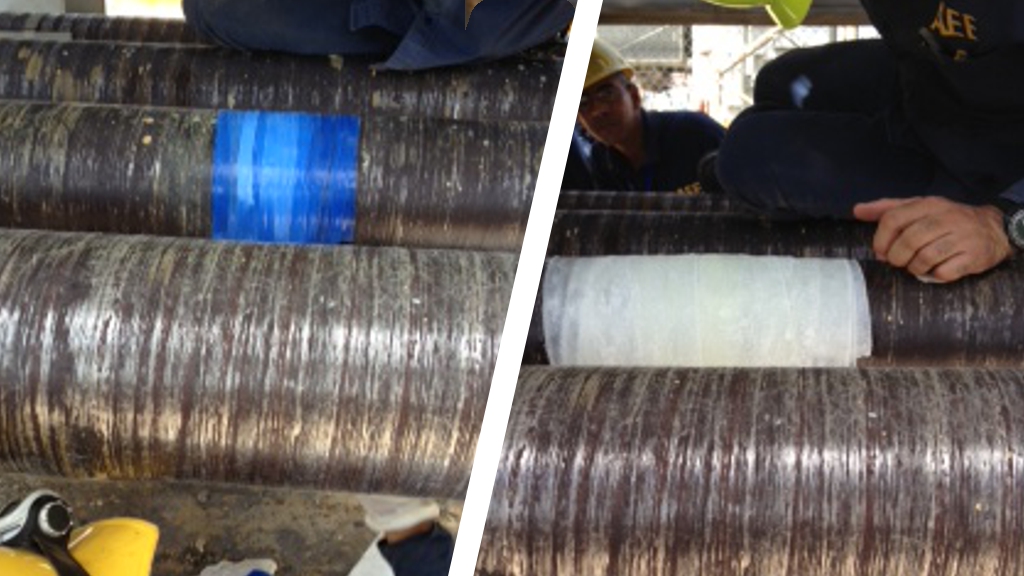

A utilities company repair and reinforce two 20 metre pipe bridges leaking sewage from corroded joints into a stream below, extending the lifespans of the structures

A church in the UK repairs and encapsulates a leaking welded joint where a 100mm cast iron pipe stepped down to a 50mm steel pipe via a 6mm thick steel plate

A farm in Norfolk repair a breached stainless steel pipe at the top off a biomass power plant via a flexible and lightweight repair from the top of a 20 feet ladder

An oil well in Argentina repair a 900mm steel pipe suffering from heavy surface damage and ruptures caused by corrosion located near a tee and welded joint

Two sections of corroded leaking pipe in a district heating system undergo repair to avoid shutting down the system in the depths of winter to fit replacement parts

A contractor repairs a ruptured section of 70mm cast iron water supply pipe before reconnecting it to the network, keeping water running for a block of flats in Essex

After ignoring a leaking joint on a badly soldered copper pipe, a property owner is spurred into a repair after noticing enough water had escaped to rot floorboards

An iconic London hotel repair a 50mm x 25mm crack in an iron wastewater pipe above a prestigious room, allowing the room to reopen to the public

A Welsh leisure centre make a live leak repair of a pressurised 50mm crack on an inaccessible 200mm PVC plastic pipe in their swimming pool filtration system

A furniture business repair a pinhole leak on a steel pipe tee in their workshop sprinkler system after initially being told the only solution was replacing the leaking section

Contractors working on a farm fix a leaking underground heating pipe with insulation lagging after cutting into it when mistakenly believing it to be a disused drainage pipe

An automotive company make a high temperature live leak repair to a pipe in their on-site CHP Plant, avoiding the need to shut down power to fit a replacement

A live leak repair to a contaminated water pipe ensured a Puerto Rico Power Station was operating at full capacity 18 months later when Hurricane Maria hit the island

A burst underground 400mm carbon steel water main undergoes a live leak repair after being considered unfixable and left to leak for 15 years