Essex Flats Ruptured Water Supply Pipe Repair & Reconnection

Contractors removed a ruptured section of 70mm cast iron pipe from a water supply line serving a block of flats in Essex, only to discover no new fittings were available because the pipe was 100-years-old. A rapid pipe repair and reconnection was required to restore water supply.

Case Study Overview

Site Block of Flats

Location Essex, UK

Pipe Type 70mm cast iron water supply pipe

Pressure 20 bar

Repair Type Leak repair and reconnection

Products Superfast Steel Epoxy Putty, Wrap & Seal Pipe Burst Tape, SylWrap HD Pipe Repair Bandage

Pipe Defect

Corrosion had caused the water supply pipe connecting a block flats to the public network to rupture, resulting in a 20 bar leak which was losing a considerable amount of water.

After inspecting the pipe, the contractor in charge decided that it was too badly damaged to repair. They removed the entire damage section with the intention of fitting a replacement.

It was only after the pipe had been cut away that the contractor discovered fittings of the size and type required were no longer available due to the pipe being a century old.

The contractor needed a repair method to seal the ruptures in the pipe and a way of reconnecting it, otherwise the block of flats would be left without running water.

SylWrap Solution

So serious was the need to reconnect the flats to the water network that the contractor drove to Sylmasta HQ in West Sussex to collect a SylWrap Pipe Repair Contractor Case for the repair.

Superfast Steel Epoxy Putty was used to repair the ruptures in the cast iron water supply pipe prior to its reconnection. Superfast Steel is a fast-working epoxy putty kneaded by hand and pushed into holes and cracks on pipework.

Within 5-10 minutes of mixing by hand, the putty begins to harden and form a cohesive bond. After 1 hour, the pipe in question can be put back into service with the putty having filled all ruptures.

Superfast Steel offers pressure resistance up to 30 bar, making it suitable for handling the 20 bar which the water supply pipe operated at. Even so, it was decided to apply additional Wrap & Seal Pipe Burst Tape over the putty.

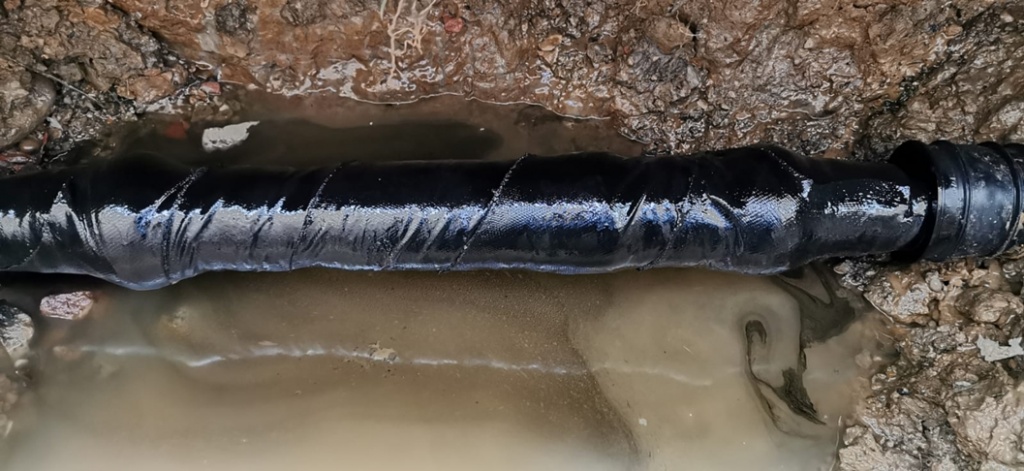

Wrap & Seal is made from self-amalgamating silicone. It stretches by 300 percent and fuses to form a solid rubber band, creating a high-pressure seal over leak areas.

The entire repair was then overwrapped with SylWrap HD Pipe Repair Bandage. SylWrap HD is water activated and sets rock-hard in minutes. It was smoothed onto the pipe to provide and impact resistant layer of protection, reinforcing the initial repair.

Wrap & Seal was used to reconnect the removed section with the rest of the water supply pipe. The tape provided a high-strength, watertight seal between the joints.

To further protect the repair, the entire section of pipe was encompassed with further SylWrap HD. Once cured, this top layer was painted black to make it a uniform colour with the rest of the pipe.

All of the products used in the repair have WRAS approval, meaning that they are certified to British standards as safe to use with drinking water. This was a legal requirement for any connection involving public water.

Outcome

Completing the entire repair took under two hours, after which water supply was restored to the flats. The contractor estimated that fabricating new replacement parts for the damaged section would have cost £12,000. The cost of the Contractor Case in comparison was under £300.

Follow Up

The contractor have now equipped themselves with further Contractor Cases for making future emergency pipe repairs.

Each Case contains enough products to make up to six live leak repairs on pipes of all diameters and types without the need for any formal training.

The Case is designed for easy storage on the van, meaning that a contractor will always have it to hand for fast response to unexpected leaks and bursts.

Video

Products Used

Superfast Steel

Fast working epoxy putty used to fill in holes and cracks on pipework

Wrap & Seal Pipe Burst Tape

Self-fusing silicone pipe repair tape for watertight reconnecting of pipe joints

SylWrap HD Bandage

Water-activated wrap sets rock hard to reinforce, protect and strengthen repairs

Universal Pipe Repair Kit

Superfast Steel, Wrap & Seal and SylWrap HD are supplied together in a Universal Kit

Pipe Repair Contractor Case

Easy-to-store case with everything needed to make up to six emergency pipe repairs

Related Case Studies

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com