Pumping House 150mm Steel Pipe Leaking Welded Saddle Joint Repair

After several failed attempts, a 150mm steel pipe leaking from both ends of a welded saddle joint outside a pumping house in Malaysia is successfully sealed by building a repair up and over the 20mm step between the line and the joint.

Case Study Overview

Site Pumping house

Location Malaysia

Pipe Type 150mm steel

Repair Type Live leak repair

Products Wrap & Seal Pipe Burst Tape

Pipe Defect

The 150mm steel pipe ran water out of the pumping house. The saddle joint had been welded in place to reinforce a capped tee and sat approximately 20mm higher than the original line.

Water was discovered to be seeping out of both ends of the joint – one of which was suffering from heavy corrosion – leaving the pipe surface noticeably wet and the ground beneath sodden.

The pipe could not be isolated or replaced because this would involve shutting down the pumping house. Several repair methods had been attempted, including a clamp and epoxy putty.

None though had been successful due to the pipe being live and the difficulty of sealing around the step. The pipe had therefore been left to slowly leak, which over time meant a significant amount of water loss.

SylWrap Solution

Whilst on a visit to Malaysia, a technician from Sylmasta was asked to accompany an engineering team to inspect the pipe and see if a solution for preventing leakage from the line could be formulated.

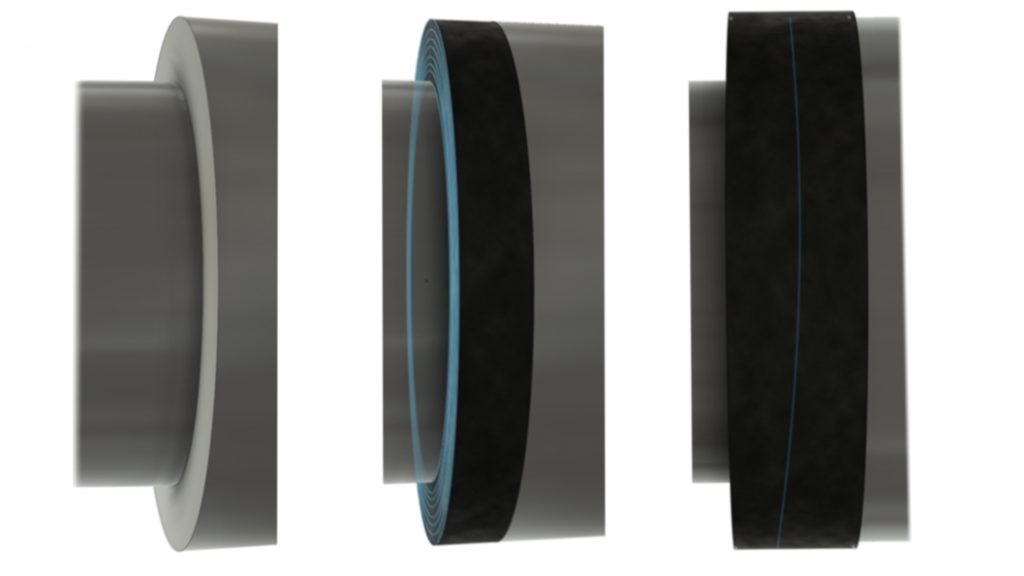

They recommended using Wrap & Seal Pipe Burst Tape to start a repair on the original steel pipe and build it up and over the weld, fully encompassing the entire step. This method would be used to seal both ends of the joint.

An angle grinder was first used to sand down the pipe, clean it of loose material and remove corrosion. A first Wrap & Seal Tape was applied on the original line directly next to the step.

As the Tape was wrapped over and fused to itself, each rotation added another layer, moving it closer to the top of the saddle. Once the 20mm step had been bridged, Wrap & Seal was applied 50mm across the saddle.

Wrapping then returned to directly over the edge of the joint. Here, a ridge was created over the leak area to increase the pressure resistance of the repair.

Three Wrap & Seal Tapes were used in total to seal one end of the saddle. Each new Wrap & Seal amalgamated with the previous Tapes applied to form a solid rubber mass around the step. The application was then repeated using another three Tapes at the other end.

Outcome

Because the welded saddle joint had been seeping slowly, there was no immediate way of checking whether the repair had been effective. The pipe therefore had to be inspected several days later.

When this took place and the pipe surface was found to be completely dry, the application was deemed a success. In less than one hour, Wrap & Seal had repaired a leak which had eluded the water company operating the pumping house for many months.

Follow Up

Leaking saddle joints are a frequent problem on the vast water network in Malaysia. The water company were understandably pleased to have a repair method which could now be used in similarly challenging applications across the country.

Products Used

Wrap & Seal Pipe Burst Tape

Waterproof silicone tape which fuses together to build repairs which seal around steps

Related Case Studies

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com