Wrap & Seal Pipe Burst Tape

Wrap & Seal Pipe Burst Tape is a self-fusing silicone pipe repair tape which seals leaking pipes of all types and diameters even when water pressure cannot be turned off.

It is twice the thickness of other self-amalgamating waterproof tapes and stretches to 300% of its length, allowing for more pressure to be applied per wrap. Using multiple tapes can build a repair capable of holding up to 30 bar.

Because Wrap & Seal is effective on live leaks, it avoids costly and disruptive shutdowns of systems. Wrap & Seal is temperature resistant to 200ºC, and is used on pipes carrying hot water and chemicals.

No prior training is required to use Wrap & Seal – simply follow the instructions supplied and apply the tape. It has WRAS Approval, meaning it is certified to British standards as safe to use on pipes carrying drinking water.

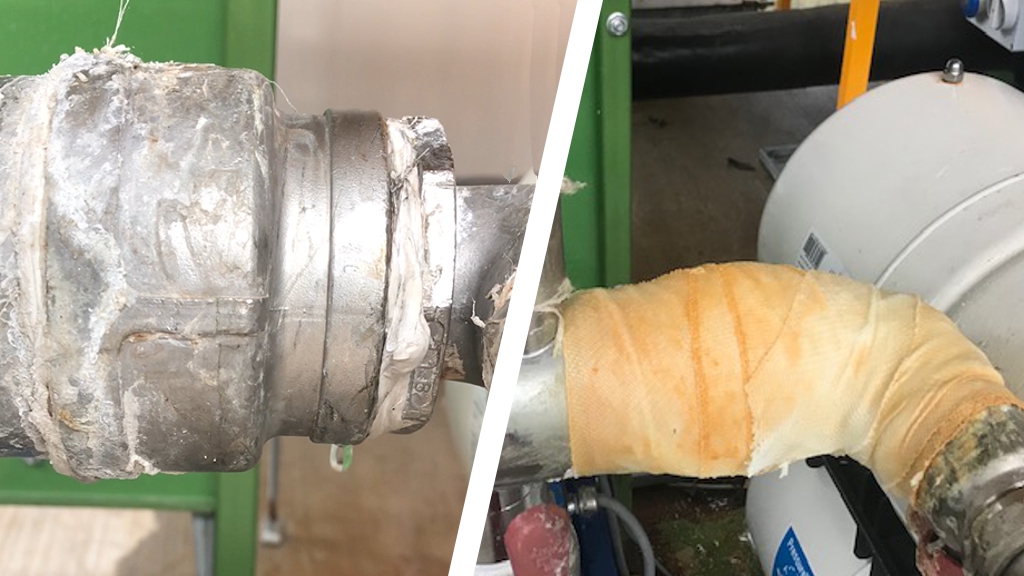

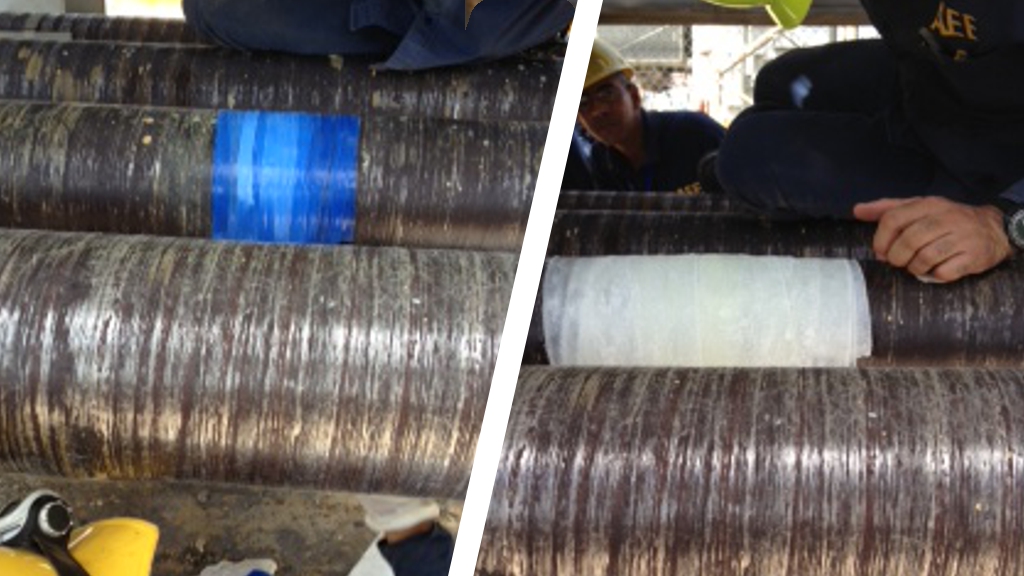

Wrap & Seal is used in applications ranging from small domestic plumbing problems to large scale industrial pipe repairs. It is effective on steel, stainless steel, copper, malleable iron, GRP, ceramic, most plastics, clay, concrete, rubber, and lead.

To reinforce pipe repairs made with Wrap & Seal, Sylmasta recommend overwrapping the Tape with a SylWrap Pipe Repair Bandage. The Bandage offers a rock hard, impact resistant layer of protection.

SylWrap can either be purchased separately, or alongside Wrap & Seal as part of the Universal Pipe Repair Kit or the Pipe Repair Contractor Case, containing enough Tapes and Bandages to make up to six repairs.

How to fix a leaking pipe using Wrap & Seal Pipe Burst Tape

Fixing a leaking pipe with Wrap & Seal Pipe Burst Tape is straightforward. Depending on the diameter of the pipe and the number of Tapes used, repairs can be made in less than 15 minutes.

The repair begins by anchoring the Wrap & Seal next to the leak area. Using the centre line of the Tape as a guide, you stretch it to its maximum and wrap tightly over the crack in the pipe until the Tape runs out.

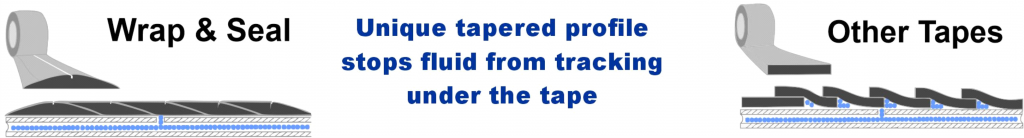

As you apply Wrap & Seal, it will fuse into a solid rubber band, sealing the leak. The unique tapered profile of Wrap & Seal stops water from tracking underneath the tape, maximising surface contact with the pipe.

Each layer of Tape increases the pressure resistance of the repair. Multiple Tapes applied on top of each other will fuse to the previous layer, building resistance. To determine how many Wrap & Seal are required to make a repair up to a certain pressure on a specific pipe diameter, please use the Repair Calculator.

When repairing holes up to 20mm on pipes in excess of 150mm, a SylPad Pressure Resistance Multiplier can be used in conjunction with Wrap & Seal. SylPad better concentrates the elastic force of the tape directly over the leak on larger diameter pipework, multiplying pressure resistance by up to three times.

Applications

- Domestic live leak repairs, including kitchen and bathroom pipes

- Industrial live leak repairs, including wastewater treatment works, quarry wash plants, dry risers, petrochemical plants, nuclear power plants, oil rigs, farms, hotels, and breweries

- Repairs to non-plumbing pipes, such as car exhausts and hoses

Benefits

- Tape is extra thick compared to other self-fusing waterproof pipe repair tapes and stretches by 300 percent

- Effective even when water flow cannot be turned off, negating the need to shutdown systems

- Quick and easy to apply – repairs can be made in under 30 minutes

- Offers a low-cost alternative to hiring a plumber or fitting replacement systems

- WRAS approved so safe to use with drinking water

Technical Data

Operating Temperature:

-90°C to 260°C.

Max Pressure Resistance:

Please use the Repair Calculator to enter your repair data.

Shore A Hardness:

55.

Tensile Strength:

9.7 MPa.

Max Elongation:

450%

Tear Strength:

175 N/m.

Bond Strength:

9N.

Adhesion Unwind:

75mm max.

Cold Brittle Point:

-54°C.

Water Absorption by Weight:

3% max.

Full TDS Downloads

Wrap & Seal Pipe Burst Tape Case Studies

Costa Rica Sugar Mill Live Leak Pipe Repair of 70mm Alcohol Line Operating at 2 Bar

Domestic Porcelain Toilet Soil Pipe Hairline Crack Around Diameter Repair

Pumping House 150mm Steel Pipe Leaking Welded Saddle Joint Repair

Water Network Underground 150mm Cement Coated Steel Pipe Live Leak Repair

Pig Farm Biodigester Tank Leaking Stainless Steel Heating Pipe Repair

Wastewater Treatment Plant Seal Pipe Flange Against Tree Root Ingress

Libya Water Supply Network Above & Below Ground Live Leak Pipe Repair

District Heating System Suspended in Ceiling Cavity Live Leak Pipe Repair

Wastewater Treatment Works Contaminated Water Pipe Live Leak Repair

Domestic Property Restricted Space Malleable Iron Water Supply Pipe Repair

Malaysia Pumping House 150mm Steel Elbow Live Pinhole Leak Repair

Libya Leaking Underground 200mm Fuel Oil Line 44 Bar Pressure Pipe Repair

Bahrain International Airport 100mm UPVC Pipe Step Joint Live Leak Repair

Inspection Pit 650mm Ductile Iron Pipe Leaking Coupling Joints Repair

Saudi Arabia Cracked 250mm PCCP Stub Live Leak Pipe Repair & Reinforcement

Hospital Burst 300mm Air Conditioning Water Return Pipe Emergency Repair

Mexico Buried 600mm Asbestos Cement Leaking Pipe Sleeve Repair

Pond Plastic Supply Hose 80mm Longitudinal Split Leak Repair

Pipe Bridges Lifespan Extension Through Leak Repair & Reinforcement

Church Central Heating Steel & Iron Welded Pipe Joint Leak Repair & Encapsulation

Argentina Oil Well 900mm Steel Pipe Repair & Surface Restoration

District Heating System Corroded Underground Pipe Leak Repair

Essex Flats Ruptured 20 bar Cast Iron Water Supply Pipe Repair & Reconnection

Domestic Heating Copper Pipe Badly Soldered Leaking Joint Repair

Leisure Centre Swimming Pool Filtration System PVC Pipe Repair

Farm Underground Heating Pipe and Insulation Lagging Repair

CHP Plant High Temperature Pipe Leaking Elbow Joint Repair

Puerto Rico Power Plant Cracked Contaminated Water Pipe Live Leak Repair

Underground Burst Water Main Repaired After 15 Years of Leaking

Wrap & Seal Repair Calculator

The below Wrap & Seal Calculator can be used to determine the recommended number of Wrap & Seal Pipe Burst Tapes required to seal a live leak based on pipe diameter and pressure.

Enter the diameter of the pipe in millimetres, water pressure and the size of the hole requiring sealing in millimetres. The safety factor is a multiple to include a margin of safety. For example, if pipe pressure is 5 bar and you want a safety factor of two, the calculator will formulate a repair capable of withstanding 10 bar.

After entering your data, selecting the size of Wrap & Seal will determine how many of that specific tape are required for your repair. Repairs being made to pipes in excess of 150mm diameter with Wrap & Seal PB-50x4m or PB-50x11m should be made in conjunction with SylPad.

Calculations serve as a guide to potential maximum pressure resistance only. Actual pressure resistance depends upon pipe material, condition, hole size, leak type and tension maintained during wrapping. If you are unsure, more than one Wrap & Seal can be used to stop the leak.

Wrap & Seal Pipe Burst Tape Size Guide

Wrap & Seal Pipe Burst Tape is currently available in the following sizes.

| Product Code | Wrap & Seal Size |

| PB/25x2HD | 25mm x 2m |

| PB/50x4HD | 50mm x 4m |

| PB/50x11HD | 50mm x 11m |

Please use the form to enquire about the price and availability of Wrap & Seal Pipe Burst Tape

Related Live Leak Repair Products

SylPad Pressure Resistance Multiplier

SylPad is used to increase the pressure resistance of Wrap & Seal Pipe Burst Tape when making live leak repairs to holes up to 20mm on pipework in excess of 150mm diameter.

Number of Repairs: One

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 200ºC

Live Leaks: Yes

SylWrap Universal Pipe Repair Kit

The Universal Pipe Repair Kit contains all the products needed to make a WRAS approved, permanent repair to burst and leaking pipes when pressure cannot be turned off.

Number of Repairs: One

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC

Live Leaks: Yes

SylWrap Pipe Repair Contractor Case

Designed for regular users, the Case is easily stored on-site or on-the-van for immediate emergency use. It contains enough products to make up to six WRAS approved permanent repairs.

Number of Repairs: Multiple

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC

Live Leaks: Yes