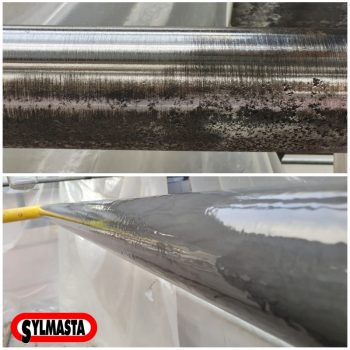

Surface Coating for Pipe Protection

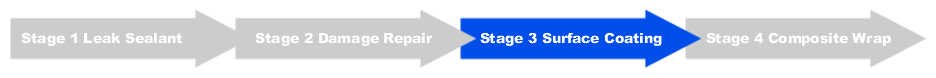

Stage 3 of the Sylmasta Pipe Refurbishment System

Surface coatings are applied to pipelines at Stage 3 of the Sylmasta Pipe Refurbishment System for protection against corrosion, chemical attack, and other environmental factors.

An epoxy coating or paste applied to a pipeline surface creates a chemically resistant outer layer, protecting against external corrosion and other forms of attack. Should internal corrosion breach the original pipe wall, the surface coating forms an impermeable membrane of containment.

Surface coatings also increase adhesion and maximise the surface contact area with the composite wrap (added at Stage 4 of the Sylmasta Pipe Refurbishment System), further strengthening the application.

Liquid Metal is a brush-applied epoxy coating with a 90 minute gel time. As well as pipe protection, it can be used in conjunction with SylWrap HD as a load-transfer layer, providing PCC-2 compliant repairs. The composite wrap is applied once Liquid Metal has gelled but remains tacky.

Titanium Supergrade HT Epoxy Paste is used in extreme temperature or more complex applications, where a longer cure time is desired. It is spread thinly over pipes using a hand tool. The composite wrap is applied to Titanium Supergrade immediately.

A surface coating is always recommended for corrosion protection and to act as an interface layer. Some engineers opt not to use a coating to reduce the cost of a repair.

Before doing so, the user must be satisfied leaks caused by internal corrosion will not occur and the pipe therefore requires no containment. The exterior pipe surface must also be in sufficiently good condition to be wrapped directly with the composite layer.

Neither Liquid Metal nor Titanium Supergrade make effective underwater repairs. Sylmasta instead recommend the use of SylWrap CR for providing corrosion protection in marine environments. SylWrap CR comes with additional corrosion inhibitors and is applied directly to pipes underwater.

Select your Surface Coating

Liquid Metal is a metal-filled epoxy coating which cures to form a smooth, metallic, hard-wearing protective surface over steel, other metals and most plastics. When applied with SylWrap HD, it can be used as a load-transfer layer providing PCC-2 compliant repairs.

Number of Repairs: Multiple

Work Time: 90 Minutes

Temperature Resistance: Up to 150°C

Titanium Supergrade HT Epoxy Paste

Titanium Supergrade HT is an alloy-reinforced epoxy paste with high compressive strength for protecting metal and plastic pipes exposed to temperatures up to 250°C. It is applied with a hand tool and has a three-hour work time for use in the most complex of applications.

Number of Repairs: Multiple

Work Time: 180 Minutes

Temperature Resistance: Up to 250°C

Once you have selected your surface coating, please move onto

Stage 4 of the Sylmasta Pipe Refurbishment System – Composite Wrap

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com