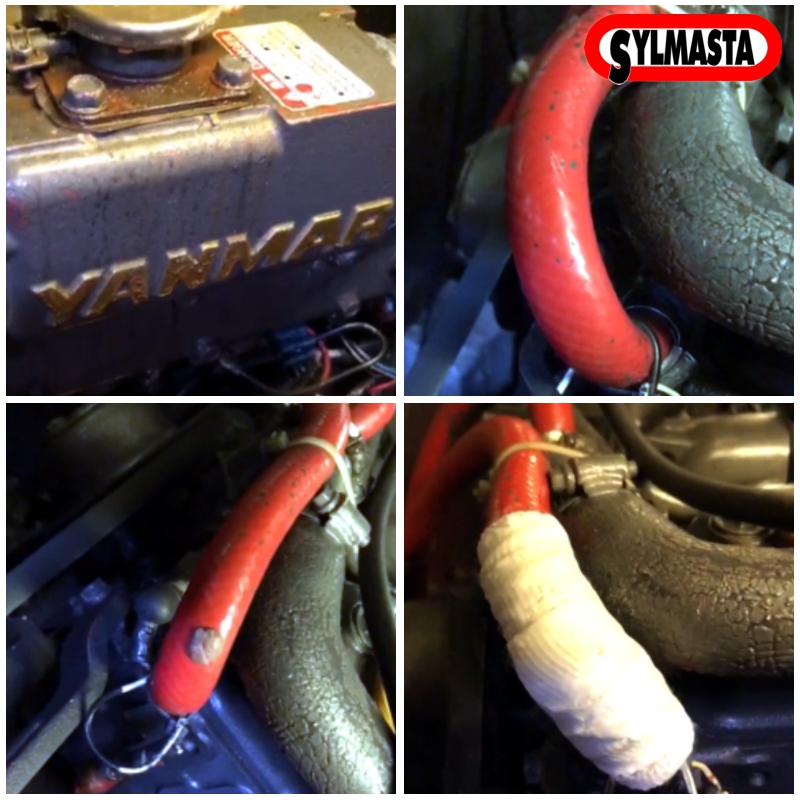

Boat Engine Pipe Repair Pinhole Leak in Rubber Cooling Hose

A boat owner makes a repair to a rubber cooling hose connected to the engine of their vessel after it developed a pinhole leak in a confined space below deck which made accessing the problem pipe difficult.

Case Study Overview

Site Boat

Location United Kingdom

Pipe Type Rubber hose

Repair Type Leak repair

Products Superfast Steel Epoxy Putty, SylWrap Pipe Repair Bandage

Pipe Defect

The rubber hose was connected to the engine and carried water as part of the cooling process. Once the pinhole leak developed, water sprayed out of the hose at high pressure whenever the engine was in service. This was dangerous and unsustainable.

Repairing the leak was made difficult because there was little room to access the hose in its location below deck surrounded by other pipes and engine components. The pinhole itself was on a bend in the hose, ruling out the use of several repair methods, including a clamp.

SylWrap Solution

A SylWrap Standard Pipe Repair Kit was delivered to the boat owner. The Kit contains all the products needed to make a permanent repair where pressure can be turned off. The Kit is versatile enough to be effective on bends and to pipes in hard-to-access areas.

The pinhole leak was first sealed using Superfast Steel Epoxy Putty. The required amount of putty was cut from the stick, kneaded by hand and applied over the pinhole whilst soft. Superfast Steel easily adhered to the rubber.

After five minutes, the putty began to harden. Before it could fully cure, a SylWrap Pipe Repair Bandage was applied over the top. The resin in SylWrap was activated with water and the bandage wrapped and smoothed around the hose.

As this happened, SylWrap forced the putty further into the pinhole. Once Superfast Steel cured, it now completely sealed the leak in the pipe.

SylWrap meanwhile set in five minutes, providing an impact resistant sleeve around the hose to increase the effectiveness of the repair and protect against future leaks.

By using Superfast Steel and SylWrap Bandage in conjunction, the boat owner had created a repair with pressure resistance up to 30 bar and temperature resistance to 120ºC. This was more than suitable for the engine hose.

Outcome

When the boat engine was started, water was no longer escaping from the hose. This indicated a successful boat pipe repair and meant that the vessel could return to the sea.

Completing the application took under 30 minutes and cost less than £30, including delivery of the SylWrap Pipe Repair Kit to the boat. This represented a considerable saving compared to quotes offered by specialist marine engineering contractors to fix or replace the hose.

Follow Up

SylWrap Pipe Repair Kits have since been used in many different applications within the marine industry, on vessels ranging from small fishing and leisure boats to super yachts worth tens of millions of pounds.

The Pipe Repair Contractor Case has proven particularly popular. It contains enough products to make up to six live leak repairs and can be conveniently stored onboard or at dockyards. Having a Contractor Case available enables problems to be fixed as soon as they arise.

Products Used

Superfast Steel

Fast working epoxy putty applied to pipes of all materials to seal leaks

SylWrap Pipe Repair Bandage

Water-activated wrap sets rock hard to reinforce, protect and strengthen repairs

Standard Pipe Repair Kit

Superfast Steel and SylWrap Bandage are supplied together in a Standard Pipe Repair Kit

Pipe Repair Contractor Case

Easy-to-store case which makes up to six emergency live leak pipe repairs

Related Case Studies

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com