Superfast Copper Epoxy Putty Stick

Superfast Copper is a fast-working epoxy putty in a 114g stick format used to seal holes, cracks and leaking joints in domestic copper pipes and smaller industrial applications.

It is copper-filled and formulated for use on non-ferrous metal pipework where water pressure can be turned off.

Superfast Copper has WRAS approval, meaning it is certified to British standards as safe to use on pipes carrying drinking water. Within an hour of application, systems repaired using Superfast Copper can be put back into use.

It is resistant to water, chemicals and temperature extremes and does not rust. It contains no solvents or VOC’s, is non-flammable and releases no noxious fumes. It will not shrink or pull away and the unused portion stays fresh for future use when saved in its original package.

To reinforce repairs made with Superfast Copper, Sylmasta recommend overwrapping the Epoxy Putty with a SylWrap HD Pipe Repair Bandage. The Bandage offers a rock hard, impact resistant layer of protection.

SylWrap HD can be purchased along with Superfast Steel Epoxy Putty as part of the SylWrap Standard Pipe Repair Kit or the Pipe Repair Contractor Case, containing enough products to make up to six pipe repairs. Superfast Steel is effective on pipes of all materials, including copper.

For larger leak sealing applications requiring a slower curing putty for more careful application, please see Sylmasta AB Original Epoxy Putty. AB Original is available in bulk quantities and has a two-hour work time for more complicated repairs.

Superfast Copper Epoxy Putty is resistant to 150°C. For extreme temperature repairs, please see Superfast Titanium Epoxy Putty Stick which offers resistance to 280°C.

How to fix a leaking pipe using Superfast Copper Epoxy Putty Stick

Superfast Copper Stick contains pre-measured portions of activator and base, meaning that no measuring or mixing is required.

To use Superfast Copper, simply cut off the required amount of Epoxy Putty and knead it by hand. As it is kneaded, the two contrasting colours will blend into a copper colour to indicate successful mixing.

Whilst soft, Superfast Copper Epoxy Putty is pushed into cracks in domestic and industrial non-ferrous pipework where it will cure, filling holes and sealing leaks.

Superfast Copper has a work life of approximately 3 minutes. Within 5-10 minutes, the Epoxy Putty will begin to harden and form a cohesive bond. After one hour, the pipe in question can be put back into service.

Once cured, Superfast Copper can be tapped, drilled, screwed, sawed, machined, ground, filed, or painted to create a smooth and seamless finish uniform with the pipe undergoing repair.

Applications

- Large domestic repairs to pipes made of copper and other non-ferrous metals, including kitchen and bathroom and heating pipes

- Industrial repairs to copper pipes, including at wastewater treatment works, quarry wash plants, dry risers, petrochemical plants, nuclear power plants, oil rigs, farms, hotels, and breweries

Benefits

- Easy to use – cut off amount of putty required, knead by hand, apply

- Repairs in 5-10 minutes. Systems can be turned back on after one hour

- Does not rust. Unused putty can be kept for a later repair

- WRAS approved so safe to use with drinking water

Technical Data

Hardness, Shore D:

80 (full cure, 24 hours).

Lap Shear Tensile Strength:

4.8 MPa (on copper),

4.5 MPa (on steel)

Compressive Strength:

83 MPa.

Density (gm/cm3/lb/gal):

1.9, 15.8.

Shrinkage:

<1%.

Non-Volatile Content:

100%.

Electrical Resistance:

30,000 megohms.

Dielectric Strength:

300 (volts/mil).

Upper Temperature Limit:

120°C continuous.

150°C intermittent.

Chemical Resistance:

Resistant to hydrocarbons, ketones, alcohols, esters, halocarbons, aqueous salt solutions and dilute acids and bases.

PDF Downloads

Superfast Copper Epoxy Putty Case Studies

Portable Horse Shower Unit Repair of Copper Pipes Burst in Freezing Weather

Oil Refinery Seawater Cooling System 3000mm GRP Return Pipe Leak Repair

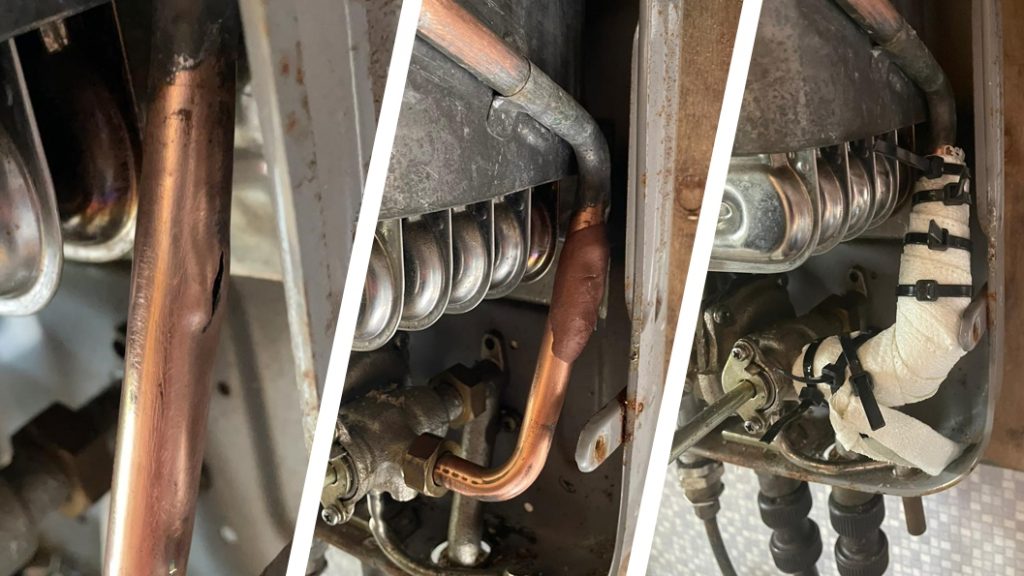

Camper Van Boiler System Cracked Leaking Copper Pipe Repair

Mexico Buried 600mm Asbestos Cement Leaking Pipe Sleeve Repair

Quarry Aggregate Wash Plant Pierced 300mm Plastic Pipe Pinhole Repair

Argentina Oil Well 900mm Steel Pipe Repair & Surface Restoration

Please use the form to enquire about the price and availability of Superfast Copper Epoxy Putty Stick

Related Leak Repair Kits

SylWrap Standard Pipe Repair Kit

The Standard Pipe Repair Kit is used to make a WRAS approved, permanent repair to burst and leaking pipes when pressure can be turned off.

Number of Repairs: One

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC

Live Leaks: No

SylWrap Universal Pipe Repair Kit

The Universal Pipe Repair Kit contains all the products needed to make a WRAS approved, permanent repair to burst and leaking pipes when pressure cannot be turned off.

Number of Repairs: One

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC

Live Leaks: Yes

SylWrap Pipe Repair Contractor Case

Designed for regular users, the Case is easily stored on-site or on-the-van for immediate emergency use. It contains enough products to make up to six WRAS approved permanent repairs.

Number of Repairs: Multiple

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC

Live Leaks: Yes