SylWrap Universal Pipe Repair Kit –

For Live Leak Repairs

The SylWrap Universal Pipe Repair Kit enables any user to make a permanent, composite repair to pipework suffering from a live leak.

Because the Universal Kit is effective when flow cannot be turned off, the draining of pipelines or tanks is not required to perform a repair. This ensures that time-consuming shutdowns of equipment are avoided and provides a cost-effective alternative to replacement.

Repairs can be completed in under 30 minutes to pipes of all sizes made of steel, stainless steel, copper, malleable iron, GRP, ceramic, most plastics, clay, concrete, rubber, and lead.

The Kit has WRAS Approval, meaning it is certified to British standards as safe to use on pipes carrying drinking water. It makes repairs pressure resistant up to 30 bar, temperature resistant to 120ºC, and is used on pipes carrying hot water and chemicals.

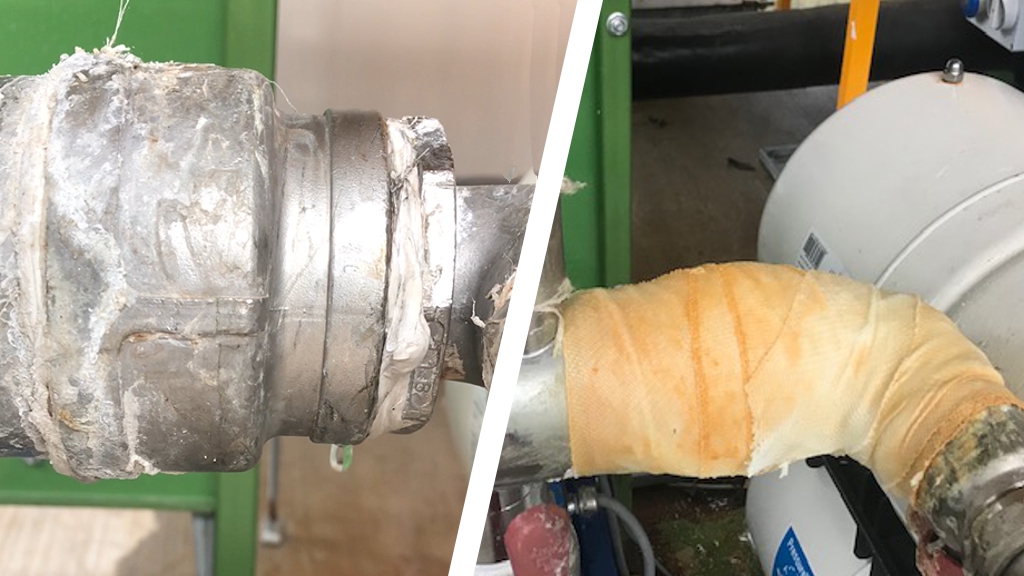

Effective repairs can be made around difficult elbow joints, tee joints and welded joints, offering a flexible alternative to heavy, bulky pipe repair clamps.

For regular pipe repair users, Sylmasta have developed the SylWrap Pipe Repair Contractor Case. The Case is easy to store on the van or on site and contains enough Universal Kit products to make up to six live leak repairs.

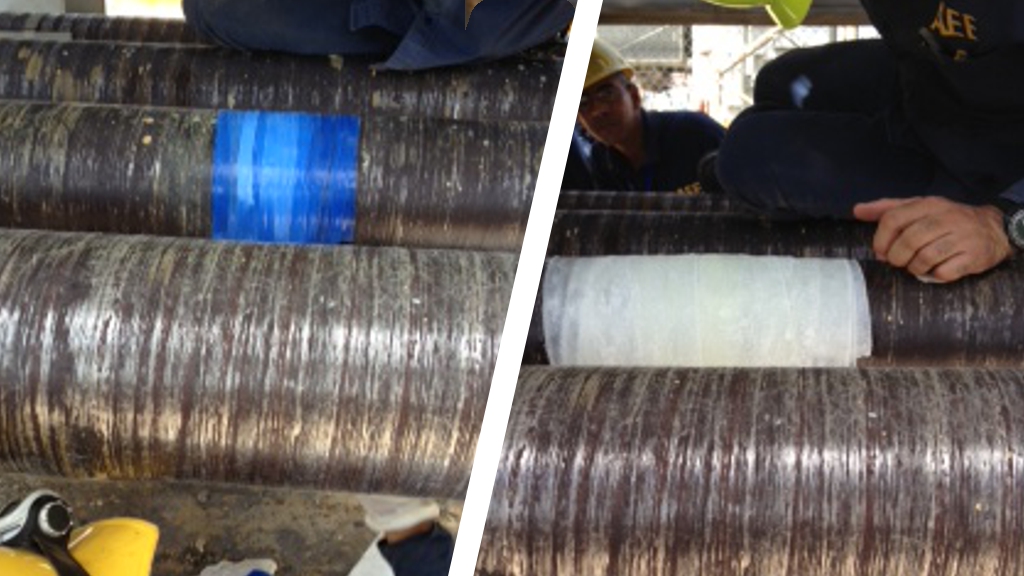

SylWrap Contractor Cases are used by several water companies in the United Kingdom for the speed and ease with which they repair live leaks on the public supply network, and they are approved by the national supplier in Malaysia for use on Kuala Lumpur’s vast pipe network.

How to make a live leak pipe repair with a SylWrap Universal Pipe Repair Kit

The SylWrap Universal Pipe Repair Kit contains two sealing materials – Superfast Steel Epoxy Putty and Wrap & Seal Pipe Burst Tape – and a SylWrap HD Pipe Repair Bandage.

Superfast Steel is an epoxy putty in a pre-formatted stick. It seals holes and cracks in pipes where water pressure can be turned off, restores surface profile on pipework badly damaged by corrosion or pitting, and removes step from joints prior to the application of Wrap & Seal.

To use, Superfast Steel is kneaded by hand until it turns a uniform colour. It is applied whilst soft, smoothed over pipework for surface restoration or pushed into cracks for leak sealing. Within 5-10 minutes, it will harden.

Wrap & Seal Pipe Burst Tape is a waterproof pipe repair tape made from self-amalgamating silicone. When pressure cannot be turned off, it is anchored next to and then wrapped directly over the leak area.

The Tape stretches by 300 percent, fusing into a solid rubber band which provides a high pressure seal over the leak. Multiple tapes applied on top of each other will fuse together, creating a live leak repair pressure resistant up to 30 bar.

For Universal Kits covering pipework in excess of 150mm, a SylPad Pressure Resistance Multiplier is included. SylPad is used in conjunction with Wrap & Seal to better concentrate the elastic force of the Tape directly over holes up to 20mm on larger diameter pipes, multiplying pressure resistance by up to three times.

If you are undertaking a high-pressure application, please go to the Repair Calculator tab and enter information about your repair to determine the number of tapes needed. Each Universal Kit comes with one Wrap & Seal; additional Tapes can be purchased separately.

After application of the sealing material, the repair is reinforced with a SylWrap HD Pipe Repair Bandage. Wetting the Bandage activates the resin. The Bandage is wrapped around and smoothed over the pipe with water, where it will set to provide a rock-hard, impact-resistant, protective layer.

Unlike other moisture cured wraps, SylWrap HD contains less than 0.1% free diisocyanate. This means it is not covered by the 2023 EU and UK REACH legislation governing the safe use of diisocyanates and requires no mandatory safety training before use. At the same time, the low hazard formulation reduces risk to operators.

Applications

- Domestic live leak repairs, including kitchen and bathroom pipes

- Industrial live leak repairs, including wastewater treatment works, quarry wash plants, dry risers, petrochemical plants, nuclear power plants, oil rigs, farms, hotels, and breweries

- Increasing the pressure resistance, chemical resistance, and longevity of pipes

Benefits

- Effective even when water flow cannot be turned off, negating the need to shutdown systems

- Easy to apply – simply follow the instructions to make a flexible, permanent pipe repair

- Repairs can be made inside 30 minutes

- Offers a low-cost alternative to hiring a plumber or fitting replacement systems

- WRAS approved so safe to use with drinking water

- Low hazard SylWrap Bandage is safer for operators and means no mandatory safety training required under 2023 safe use of diisocyanate legislation

Technical Data

SylWrap Working Time:

2-5 minutes, dependent upon size of SylWrap, temperature of water and pipework.

Functional Cure:

30-45 minutes.

Full Cure:

24 hours (maximum properties).

Cured Material Life:

10-20 years, dependent upon repair quality, repair thickness, condition of pipe, environmental conditions, pipe temperature, etc.

Max Service Temperature:

120°C / 250°F.

Max Pressure Resistance:

30 bar (435 psi) using Superfast Epoxy Putty depending upon nature of leak. For live leaks using Wrap & Seal, please use the Repair Calculator to enter your repair data.

Chemical resistance: Acetone, ammonia, sulphuric acid (30%), ethyl alcohol, mineral spirits, gasoline, MEK, toluene, diesel, hydrochloric acid, Varsol, ethylene glycol, crude oil, hydraulic oil (test period of 40 days).

Full TDS Downloads

SylWrap Universal Pipe Repair Kit Case Studies

Water Network Underground 150mm Cement Coated Steel Pipe Live Leak Repair

Pig Farm Biodigester Tank Leaking Stainless Steel Heating Pipe Repair

Wastewater Treatment Plant Seal Pipe Flange Against Tree Root Ingress

Libya Water Supply Network Above & Below Ground Live Leak Pipe Repair

District Heating System Suspended in Ceiling Cavity Live Leak Pipe Repair

Wastewater Treatment Works Contaminated Water Pipe Live Leak Repair

Malaysia Pumping House 150mm Steel Elbow Live Pinhole Leak Repair

Libya Leaking Underground 200mm Fuel Oil Line 44 Bar Pressure Pipe Repair

Mexico Buried 600mm Asbestos Cement Leaking Pipe Sleeve Repair

Pond Plastic Supply Hose 80mm Longitudinal Split Leak Repair

District Heating System Corroded Underground Pipe Leak Repair

Essex Flats Ruptured 20 bar Cast Iron Water Supply Pipe Repair & Reconnection

Leisure Centre Swimming Pool Filtration System PVC Pipe Repair

Farm Underground Heating Pipe and Insulation Lagging Repair

CHP Plant High Temperature Pipe Leaking Elbow Joint Repair

Puerto Rico Power Plant Cracked Contaminated Water Pipe Live Leak Repair

Underground Burst Water Main Repaired After 15 Years of Leaking

Wrap & Seal Repair Calculator

The below Wrap & Seal Calculator can be used to determine the recommended number of Wrap & Seal Pipe Burst Tapes required to seal a live leak based on pipe diameter and pressure.

Enter the diameter of the pipe in millimetres, water pressure and the size of the hole requiring sealing in millimetres. The safety factor is a multiple to include a margin of safety.

For example, if pipe pressure is 5 bar and you want a safety factor of two, the calculator will formulate a repair capable of withstanding 10 bar.

After entering your data, selecting the size of Wrap & Seal will determine how many of that specific tape are required for your repair. Repairs being made to pipes in excess of 150mm diameter using Wrap & Seal PB-50x4m or PB-50x11m should be made in conjunction with SylPad.

Each Universal Kit comes with one Wrap & Seal. If the Calculator determines that you need more than one Wrap & Seal for your repair, consider using additional tapes.

Calculations serve as a guide to potential maximum pressure resistance only. Actual pressure resistance depends upon pipe material, condition, hole size, leak type and tension maintained during wrapping. If you are unsure, more than one Wrap & Seal can be used to stop the leak.

TDS Downloads

SylWrap Universal Pipe Repair Kit Size Guide

The below size guide details the size of SylWrap LH contained within each Universal Pipe Repair Kit and the diameter of pipe each Kit is designed to repair.

| Product Code | SylWrap Bandage Size | Wrap & Seal Size | Includes SylPad | Repairs Pipe Diameter |

| SYL-106-UP | 25mm x 1.8m | 25mm x 2m | No | Up to 15mm |

| SYL-206-UP | 50mm x 1.8m | 25mm x 2m | No | 15 – 25mm |

| SYL-212-UP | 50mm x 3.6m | 25mm x 2m | No | 25 - 50mm |

| SYL-309-UP | 75mm x 2.7m | 25mm x 2m | No | 25 – 50mm |

| SYL-312-UP | 75mm X 3.6m | 25mm x 2m | No | 50 - 75mm |

| SYL-412-UP | 100mm x 3.6m | 25mm x 2m | No | 50 – 100mm |

| SYL-416-UP | 100m x 5.0m | 25mm x 2m | No | 75 - 125mm |

| SYL-616-UP | 150mm x 5.0m | 25mm x 2m | No | 100 – 150mm |

| SYL-633-UP | 150mm x 10.0m | 50mm x 4m | Yes | 150 – 300mm |

| SYL-866-UP | 200mm x 20.0m | 50mm x 11m | Yes | 300 – 600mm |

TDS Downloads

Please use the form to enquire about the price and availability of the SylWrap Universal Kit

Related Leak Repair Kits

SylWrap Standard Pipe Repair Kit

The Standard Pipe Repair Kit is used to make a WRAS approved, permanent repair to burst and leaking pipes when pressure can be turned off.

Number of Repairs: One

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC

Live Leaks: No

SylWrap Pipe Repair Contractor Case

Designed for regular users, the Case is easily stored on-site or on-the-van for immediate emergency use. It contains enough products to make up to six WRAS approved permanent repairs.

Number of Repairs: Multiple

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC

Live Leaks: Yes

SylWrap Drain & Waste Pipe Repair Kit

The Drain & Waste Pipe Repair Kit is a specialist kit for end-users such as facilities management teams frequently required to seal cracks and splits in cast iron and plastic drain, waste and soil pipes.

Number of Repairs: Multiple

Pressure Resistance: Up to 30 bar

Temperature Resistance: Up to 120ºC

Live Leaks: Yes