SylWrap HD Pipe Repair Bandage

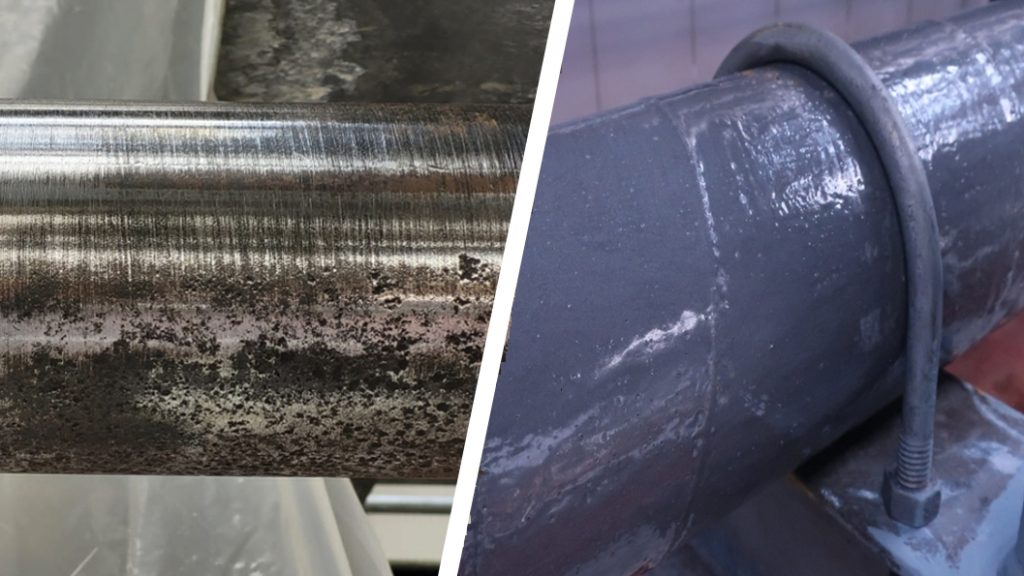

SylWrap HD Pipe Repair Bandage is a water-activated composite wrap with low free diisocyanate content below 0.1% which strengthens and protects pipework, extending the lifespan of systems.

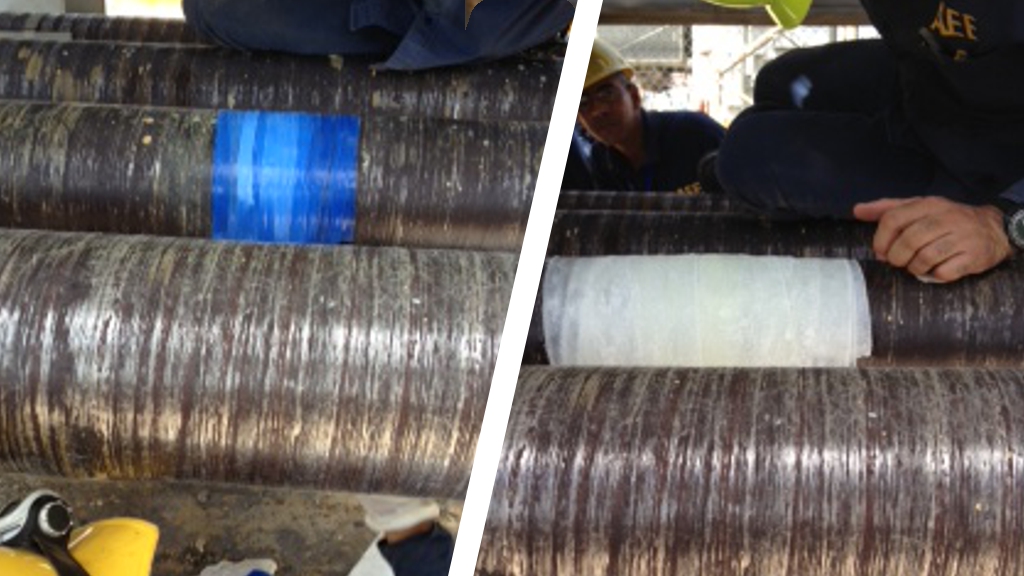

Applying SylWrap HD to a pipe increases pressure resistance, chemical resistance and hoop strength. It will reinforce leak and damage repairs made using epoxy putties, pastes, coatings, or pipe repair tape by providing a rock-hard, impact resistant layer over initial sealant materials.

The fast-working resin infused in SylWrap HD begins to cure within minutes, allowing for rapid repairs to be made. Unlike other moisture cured repair wraps, SylWrap HD contains less than 0.1% free diisocyanate.

This means SylWrap HD is not covered by the 2023 EU and UK REACH legislation governing the safe use of diisocyanates and requires no mandatory safety training before use. At the same time, the low hazard formulation offers reduced risk to operators.

SylWrap HD is temperature resistant to 120°C and effective on pipes of all sizes made of steel, stainless steel, copper, malleable iron, GRP, ceramic, most plastics, clay, concrete, rubber, and lead.

Water utilities companies in the United Kingdom keep SylWrap HD on their vans for reinforcing repairs to leaking pipes and burst water mains. SylWrap HD has WRAS Approval, meaning it is certified to British standards as safe to use on pipes carrying drinking water.

Desalination plants, wastewater treatment works, nuclear power plants, oil refineries and fire stations have all used SylWrap HD for pipeline reinforcement. The high chemical resistance of the Bandage enables it to repair hydrogen lines and sulphuric acid lines.

Sylmasta manufacture a specialist composite repair wrap for use in marine applications. SylWrap CR is infused with corrosion inhibitors to protect and strengthen metalwork against all forms of corrosion.

How to strengthen and protect pipework with SylWrap HD

SylWrap HD is easy to use. Dipping the Bandage into water activates the resin. The Bandage is then wrapped around the pipework requiring strengthening or protection with further water used to smooth it down as the application continues.

SylWrap HD has a work time of 2-5 minutes. A functional cure is achieved in 30 minutes and a full cure with maximum properties in 24 hours.

To determine the quantity of SylWrap HD and Bandages sizes for a specific reinforcement or strengthening application, please go to the Repair Calculator Tab and enter your data.

Applications

- Steel pipe repair, copper pipe repair, PVC plastic pipe repair, steel pipe repair, iron pipe repair, GRP pipe repair, ceramic pipe repair, concrete pipe repair, lead pipe repair, rubber pipe repair

- Underwater pipeline strengthening and refurbishment

- Increasing pressure resistance, chemical resistance and hoop strength

- Protection of structures other than pipes, such as machinery and piles

Benefits

- Easy to use – simply activate the Bandage using water and wrap

- Applied in under 30 minutes

- Refurbishment of pipes offers a cost-effective alternative to system replacement

- WRAS approved so safe to use with drinking water

- Low hazard formulation is safer for operators and means no mandatory safety training required under 2023 safe use of diisocyanate legislation

Technical Data

Working Time:

2-5 minutes, dependent upon size of SylWrap, temperature of water and pipework.

Functional Cure:

30-45 minutes.

Full Cure:

24 hours (maximum properties).

Cured Material Life:

10-20 years, dependent upon repair quality, repair thickness, condition of pipe, environmental conditions, pipe temperature, etc.

Shore D Hardness:

70.

Tensile Strength:

250MPa.

Coefficient of Thermal Expansion:

7.1 x 10/ °C (SylWrap composite wrap)

Max Service Temperature:

120°C / 250°F.

Max Pressure Resistance:

30 bar (430 psi), depending on size of pipe and leak (hole requires epoxy filler first).

Chemical resistance: Acetone, ammonia, sulphuric acid (30%), ethyl alcohol, mineral spirits, gasoline, MEK, toluene, diesel, hydrochloric acid, Varsol, ethylene glycol, crude oil, hydraulic oil (test period of 40 days).

Full TDS Downloads

SylWrap Pipe Repair Bandage Case Studies

Hospital Seal 1.05-Metre Long Crack in Cast Iron Downpipe Leaking Rainwater into Ward

Water Company Ductile Pipe System in Underground Pumping Station Corrosion Protection

Costa Rica Sugar Mill Live Leak Pipe Repair of 70mm Alcohol Line Operating at 2 Bar

London Cottages Corroded 48 Metre Long Shared Water Supply Pipe Leak Repair

Industrial Plant Refurbish 3 Metre Section of Corroded Steel Gas Pipe in CHP System

Water Network Underground 150mm Cement Coated Steel Pipe Live Leak Repair

Portable Horse Shower Unit Repair of Copper Pipes Burst in Freezing Weather

Pig Farm Biodigester Tank Leaking Stainless Steel Heating Pipe Repair

Argentina Chroming Factory Reinforce Welded Corners in Chromic Acid Tank

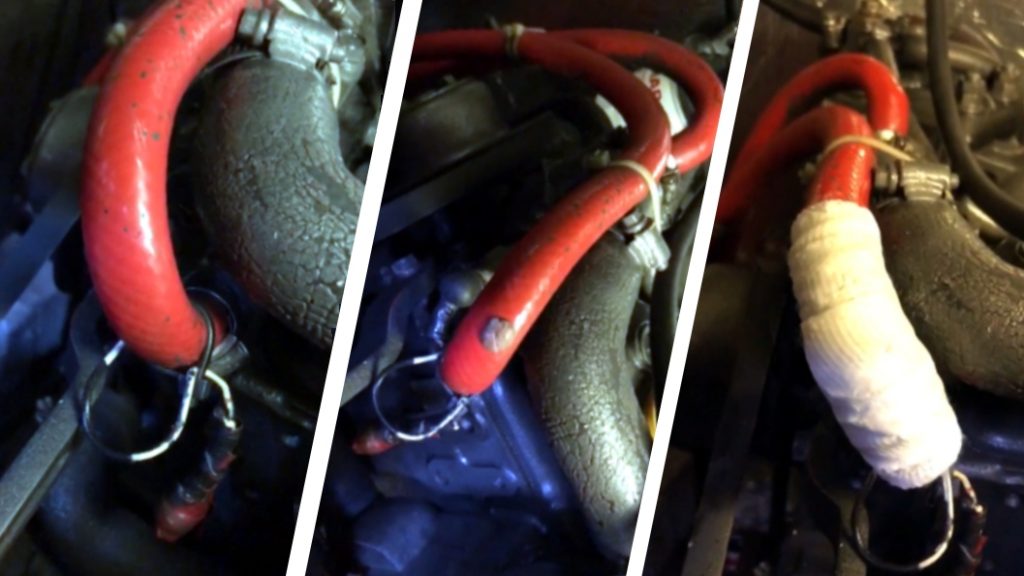

Boat Engine Pipe Repair Pinhole Leak in Bend of Rubber Cooling Hose

Wastewater Treatment Plant Seal Pipe Flange Against Tree Root Ingress

Landfill Site Encapsulate Decommissioned Drainage System Capped Pipe Stub

Chemical Plant Repair 350mm Steel Effluent Pipe Running Under Salt Marshes

Libya Water Supply Network Above & Below Ground Live Leak Pipe Repair

Puerto Rico Power Station Cooling System Leaking Hydrogen Line Pipe Repair

Fire Station Water Pumping House Corroded Steel Pipe Reinforcement

Quarry Wash Plant 150mm Steel Pipe 90 Degree Elbow Bend Leak Repair

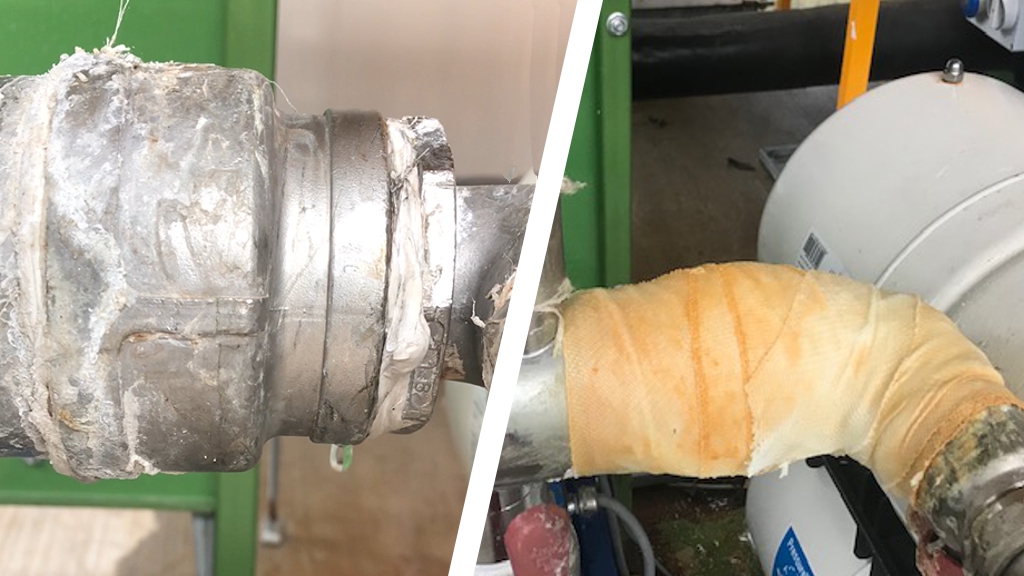

District Heating System Suspended in Ceiling Cavity Live Leak Pipe Repair

90-year-old Cracked Malleable Iron Private Water Supply Pipe Repair

Wastewater Treatment Works Contaminated Water Pipe Live Leak Repair

Seawater Cooling System 1500mm Pipe Supply Line Leak Repair & Reinforcement

Malaysia Pumping House 150mm Steel Elbow Live Pinhole Leak Repair

Libya Leaking Underground 200mm Fuel Oil Line 44 Bar Pressure Pipe Repair

Bahrain International Airport 100mm UPVC Pipe Step Joint Live Leak Repair

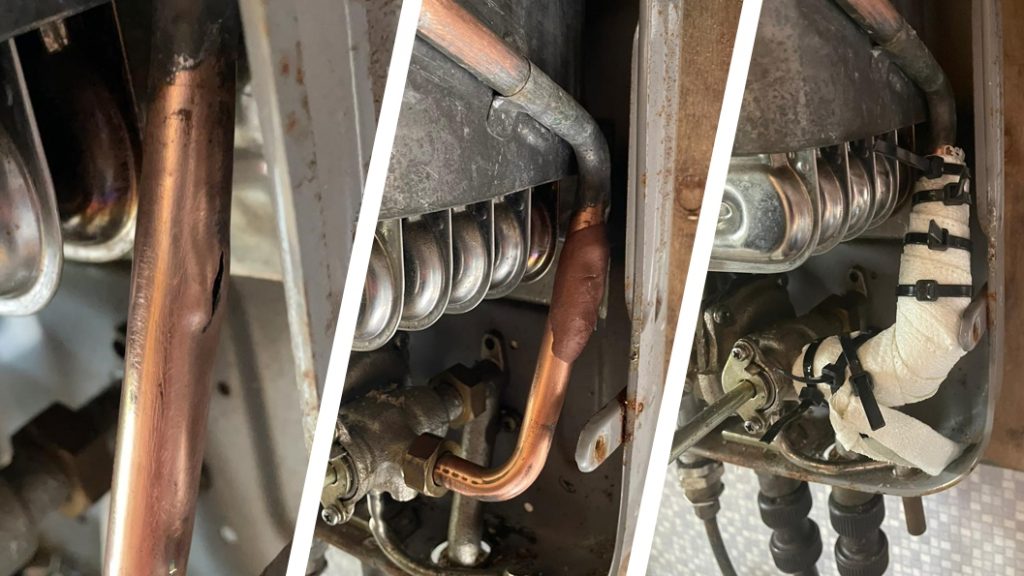

Camper Van Boiler System Cracked Leaking Copper Pipe Repair

Petrochemical Refinery 100mm Sulphuric Acid Line Pipe Elbow Reinforcement

Inspection Pit 650mm Ductile Iron Pipe Leaking Coupling Joints Repair

Saudi Arabia Cracked 250mm PCCP Stub Live Leak Pipe Repair & Reinforcement

Hospital Burst 300mm Air Conditioning Water Return Pipe Emergency Repair

Mexico Buried 600mm Asbestos Cement Leaking Pipe Sleeve Repair

Quarry Aggregate Wash Plant Pierced 300mm Plastic Pipe Pinhole Repair

Pond Plastic Supply Hose 80mm Longitudinal Split Leak Repair

Valve Chamber Below Specification 22 Degree Elbow Bends Reinforcement

Pipe Bridges Lifespan Extension Through Leak Repair & Reinforcement

Church Central Heating Steel & Iron Welded Pipe Joint Leak Repair & Encapsulation

Argentina Oil Well 900mm Steel Pipe Repair & Surface Restoration

District Heating System Corroded Underground Pipe Leak Repair

Essex Flats Ruptured 20 bar Cast Iron Water Supply Pipe Repair & Reconnection

London Hotel Cracked Cast Iron Wastewater Pipe Elbow Repair

Leisure Centre Swimming Pool Filtration System PVC Pipe Repair

Furniture Factory Steel Sprinkler System Pipe Pinhole Leak Repair

Farm Underground Heating Pipe and Insulation Lagging Repair

CHP Plant High Temperature Pipe Leaking Elbow Joint Repair

Puerto Rico Power Plant Cracked Contaminated Water Pipe Live Leak Repair

Underground Burst Water Main Repaired After 15 Years of Leaking

SylWrap Pipe Repair Bandage Repair Calculator

The below SylWrap Coverage Calculator can be used to determine the optimum SylWrap HD repair for a pipe reinforcement or strenghthening application.

Enter the diameter of the pipe in millimetres, the length of the area to be wrapped in millimetres and the pressure which the pipeline operates under.

The safety factor is a multiple to include a margin of safety. For example, if pipe pressure is 5 bar and you want a safety factor of two, the calculator will formulate a repair capable of withstanding 10 bar.

Once you have entered your data, the calculator will show you the SylWrap Bandage which is recommended for your application, the required thickness of repair, the number of layers to reach the stated thickness and the quantity of bandages required.

If you wish to see the repair requirements for a specific bandage, the SylWrap size can be changed. The calculator will then determine the repair thickness, number of layers and quantity of bandage required.

Full TDS Downloads

SylWrap HD Pipe Repair Bandage Size Guide

SylWrap HD is currently available in the following sizes recommended for use on the specified pipe diameters.

Single SylWrap HD can also be purchased as part of the Universal Pipe Repair Kit which includes Superfast Steel Epoxy Putty and Wrap & Seal Pipe Burst Tape for fixing live leaks.

| Product Code | SylWrap Size | Pipe Diameter |

| SYL106HD | 25mm x 1.8m | Up to 15mm Pipes |

| SYL206HD | 50mm x 1.8m | 15 – 25mm Pipes |

| SYL212HD | 50mm x 3.6m | 25 – 50mm Pipes |

| SYL309HD | 75mm x 2.7m | 25 – 50mm |

| SYL312HD | 75mm x 3.6m | 50 – 75mm |

| SYL412HD | 100mm x 3.6m | 50 – 100mm |

| SYL416HD | 100mm x 5.0m | 75 – 125mm |

| SYL616HD | 150mm x 5.0m | 100 – 150mm |

| SYL633HD | 150mm x10.0m | 150 – 300mm |

| SYL866HD | 200mm x 20m | 300 – 600mm |

| SYL1266HD | 300mm x 20m | Larger Pipes |

Please use the form to enquire about the price and availability of SylWrap HD Pipe Repair Bandage

Related Composite Repair Products

SylWrap CR Corrosion Protection Wrap

SylWrap CR is a pipe repair bandage infused with corrosion inhibitors to further protect pipes in harsh, aggressive environments including marine and underwater against substrate corrosion.

Number of Repairs: One Per Bandage

Requires Diisocyanate Training: No

Work Time: 2–5 minutes

Temperature Resistance: Up to 120°C

SylShield Pipe Weld & Protection Wrap

SylShield is three times the thickness of SylWrap. It is used to protect welds and pipelines which are subjected to intense installation processes or operate in highly abrasive environments.

Number of Repairs: One Per Bandage

Requires Diisocyanate Training: No

Work Time: 2–5 minutes

Temperature Resistance: Up to 120°C

E190 Epoxy Composite Repair Kit

Kit containing high-strength Sylmasta E190 Brushable Epoxy Resin and Fibreglass Tape. When used in conjunction, the two products enable more versatile patch repairs to complex sections of pipework or tanks where direct wrapping with a bandage is not possible.

Number of Repairs: Multiple

Requires Diisocyanate Training: No

Work Time: 30 minutes

Specialist resins can be formulated for temperature, chemical resistance, etc.